- Creality Ender vs Anet A8 [2022]: Which is Better? - April 14, 2022

- TEVO Tornado Review [2022] All You Need To Know - April 6, 2022

- Anet A6 Review [2022 UPDATED Version] - April 5, 2022

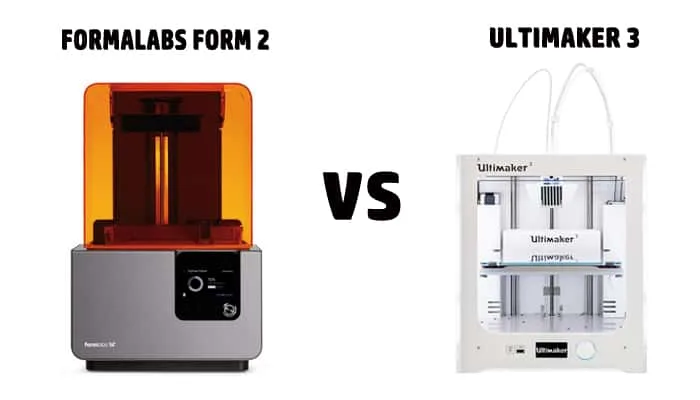

The Formalabs Form 2 and the Ultimaker 3 are both two very high end 3D printers, capable of printing the most demanding and complex objects. But there is a big difference between the two, and that is that they work in a fundamentally different way.

The Ultimaker 3 uses the more standard approach of 3D printing, called FDM, which means the material is heated up and extruded on layers to create an object.

The Formlabs Form 2 uses a completely different approach, called SLA, which basically means that there is a liquid resin that gets heated up with a powerful laser to make solid layers. This means that each printer and each technique has its own advantages and disadvantages.

In the following sections, we will list the features of each 3D printer as well as a comparison between the two, including a comparison of their features, their Pros, and Cons. At the very end, you will find the final summary and rating of each 3D printer respectively.

Bottom Line Up Front: I personally prefer the more reliable and highly rated Ultimaker 3 Extended available here. Formlabs was a great idea in concept, but largely has failed to execute in terms of reliability.

I'll be honest, the Ultimaker 3 is one of my FAVORITE 3D Printers of all time. Not trying to hype it, but it's still the go-to for reliable performance and durability over time. It actually gets BETTER the MORE you use it... Weird!

Table of Contents

Core Features of the Formlabs Form 2 3D Printer

Print Volume: The Formlabs Form 2 features a pretty big 5.7 x 5.7 x 6.9 Inch (145x145x175 mm) build platform. While it might not look big, it is important to remember that this is not a standard filament-based 3D printer. It is one of the biggest, if not the biggest available print volume for an SLA 3D printer on the market right now.

Resolution: This is where this printer really shines. Forget everything you knew about high-resolution prints on traditional filament-based printers. Since the Form 2 prints using a resin combined with a very precise laser, the resolution and amount of detail that this 3D printer can output is insane.

When printing at its highest resolution at 25 microns, it is almost impossible to make out the layers of an item without getting a close look. The layers are perfect and there are no visible artifacts from all the fused layers.

Printing transparent: That’s right, this 3D printer can print object in translucent or even fully transparent materials. This is achieved thanks to the resin that is used, and the fact that the material does not need to be melted for each layer, but is instead hardened extremely quickly by a powerful laser.

Automated Resin System: Since we are dealing with a liquid resin and not a solid material, handling and replacing the resin is a much harder task. Thankfully, Formlabs has provided this printer with a full automated resin system, which allows the user to change the resin cartridge without spilling the resin.

It also actively monitoring the available resin, and it even knows how much resin will be needed before a print, letting the user know how much will be used and if it is enough. The system is also open, allowing users to experiment with 3rd party resins.

Simple Control: Formlabs Form 2 offers an easy to use interface, with just a simple touch screen and one button. From the touchscreen, the user can select and start a print, as well as set settings and get information about the performance of the printer.

There is also the possibility to wirelessly connect to the 3D printer and control it from anywhere in a local network, from a pc, laptop or smartphone.

Formlabs Form 2 Key Specifications

- Printing Technology: SLA (Stereolithography)

- Build Area: 5.7 x 5.7 x 6.9 Inch (145 x145 x 175 mm)

- Layer Resolution: 25, 50, 100 microns (0.025, 0.050, 0.10 mm)

- Laser Spot Size (FWHM): 140 microns (0.14 mm)

- Laser Specifications: 405nm violet laser, 250mW laser

- Operating Temperature: Auto-heats to 95° F (35°C)

- Temperature Control: Self-heating Resin Tank

- Supported material: 1 L resin cartridges

- Product Dimensions: 350 × 330 × 520 mm (13.5 × 13 × 20.5 inches)

- Connectivity: USB, Ethernet, WiFi (b/g/n)

- Software: PreForm

Core Features of the Ultimaker 3 3D Printer

Build Platform: The Ultimaker 3 features a 8.5 x 8.5 x 8 Inch (215 x 215 x 200 mm) build platform. This size is one of the largest on the market when it comes to desktop 3D printers without going into modified printers. A build platform that big allows the user to print some pretty big objects at one go, without having to split it to parts.

Dual Extrusion: Most 3D printers, especially high-end ones, have the option to be upgraded to support dual extrusion. Ultimaker took this a step forward by including a very smart and small dual extruder on the Ultimaker 3 as standard.

The dual extruder allows printing using two materials at the same time, giving unlimited options to its users and their creativity.

Material Support: As with the older Ultimakers, the Ultimaker 3 supports a wide variety of filaments by default. This is achieved thanks to the improved filament feeder, the improved print head, and a heated glass bed. This ensures that this printer can print any simple and exotic material out there.

The printer also has an NFC scanner that can be used to recognize the filament it is using, so that Cura, Ultimakers recommended software, can select the profile that fits that particular print job.

Active leveling: This is a welcome feature to the Ultimaker family. All of the previous models required manual print bed calibration. While that process was very easy and straightforward, you will not have to worry about it anymore. With active leveling, the printer performs a few tests and automatically calibrates itself.

The calibration not only calibrates the bed but the 2 nozzles that are present. A few sensors and some very clever software engineering were all that was needed to make this work like magic!

Camera: Yes, this 3D printer comes with a camera. Anyone who is familiar with 3D printing will tell you that they wish they could have a look at their print when they are not in the same room as the printer.

Well Ultimaker saw that the community wanted a camera, so they added their own camera inside the printer, that allows the user to check the progress of the 3D print from their smartphone or computer using their software

Software: As before, Ultimaker gives users as many options as they want. The printer can read basic G-code, and it supports almost any slicing software that generates G-code. Cura is also an amazing piece of software that over the last few years has advanced enough to be one of the most used slicers.

Ultimaker 3 Key Specifications

- Printing Technology: FDM (Fused Deposition Modeling)

- Build Area: 8.5 x 8.5 x 8 Inch (215 x 215 x 200 mm)

- Layer Resolution: 200 to 20 micron (0.2 to 0.02 mm)

- Printing Speed: 30-300 mm/s

- Filament Diameter: 2.85mm

- Position precision: X, Y: 12.5 microns, Z: 2.5 micron

- Max Extruder Temperature: 536°F (280°C)

- Max Platform Temperature: 212°F (100°C)

- Nozzle Diameter: 0.40mm

- Operating sound: 50 dBA

- Supported materials: PLA, ABS, CPE, CPE+, PC, Nylon, TPU 95A

- Product Dimensions: 342 x 505 x 505 mm (13.5 x 19.4 x 20 inches)

- Connectivity: USB, SD Card, WiFi (b/g/n)

- Software: Cura

I'll be honest, the Ultimaker 3 is one of my FAVORITE 3D Printers of all time. Not trying to hype it, but it's still the go-to for reliable performance and durability over time. It actually gets BETTER the MORE you use it... Weird!

Comparison Formlabs Form 2 vs Ultimaker 3

Size: We will start by comparing the size, shape, and design of these 3D printers. Both printers are designed in a clean and modern way, hiding away all the electronics and cables and providing a clean look.

The Ultimaker 3 is overall bigger in size compared to the Formlabs Form 2, but this is understandable since the Ultimaker has a much larger print volume.

Print Volume: As mentioned above, the Ultimaker 3 has almost twice as much print area as the Formlabs Form 2. It should also be mentioned that this is not a bad design by Formlabs and that this is a by-product of the different printing technology and its requirements.

FDM vs SLA: Now let’s talk about the biggest difference between the two. The Ultimaker 3 using a rather traditional technique for printing, which is to have a solid material melted and layered on a build platform one layer at a time.

This has many advantages, such as cheap materials, fast prints as well as support for printing using multiple materials at once. The Formlabs For 2 on the other hand uses a technique called SLA. The way an SLA printer works is that the build platform is submerged in a resin.

A powerful laser is used to draw each layer onto the resin. When the resin is hit by the laser, it hardens and thus makes a layer. Then the build platform starts to move and the laser draws each layer on top of each other. The biggest advantage of SLA printing is the quality of the prints.

Using such a printer, objects can be printed in such fine resolution that there is no way to see the individual layers, which is very common in FDM printers. Using a resin for printing also allows for printing into translucent materials, something FDM printers are not great at since the layers cause distortions and visible lines.

Software: Both 3D printers are able to print simple .stl or .obj files. However, while the Ultimaker 3 is open source and any slicing software can be used, is not advised to do the same when printing on the Formlabs Form 2.

Since the Form 2 has different requirements and is being printed with a different mindset, it is advised to use the included software suite to slice objects before printing them.

Price: The Ultimaker 3 Extended costs around $4,500 check here for the latest price and the Formlabs Form 2 costs a hefty $3.599 (check here for the latest price). The price is very similar, but it should also be noted that the resin cartridges for the Form 2 are very expensive compared to the readily available filaments for the Formalabs Form 2.

Formlabs Form 2 vs Ultimaker 3 Comparison – Breakdown

Brand/Model |  |  |

|---|---|---|

| Build Area | 5.7 x 5.7 x 6.9 Inch | 8.5 x 8.5 x 8 Inch |

| Printing Speed | 30-300 mm/s | 30-300 mm/s |

| Layer Resolution | 25, 50, 100 microns | 200 to 20 microns |

| Supported Materials | 1 L resin cartridges | PLA, ABS, CPE, CPE+, PC, Nylon, TPU 95A |

| Extruders | Single | Dual |

| Nozzle Diameter | N/A | 0.40mm |

| Open/Closed System | Open | Open |

| Product Dimensions | 13.5 × 13 × 20.5 inches | 13.5 x 19.4 x 20 inches |

| Price | About $3,500. Check out the latest. | About $3,500. Check out the latest |

| Ratings | Speed: 9/10 Build Area: 8.5/10 Precision: 9/10 Value: 8.8/10 | Speed: 8/10 Build Area: 7/10 Precision: 10/10 Value: 9/10 |

The Final Print

Both 3D printers are capable of producing extremely high-quality prints and can be used by both beginners as well as experienced and professional users.

The Ultimaker 3 is more suitable for users looking for fast, reliable and quality prototyping, while the Formlabs Form 2 is more suitable towards people that need very precise and high-quality prints.

Bottom Line: I personally prefer the more reliable and highly rated Ultimaker 3 Extended available here. Formlabs was a great idea in concept, but largely has failed to execute in terms of reliability.

I'll be honest, the Ultimaker 3 is one of my FAVORITE 3D Printers of all time. Not trying to hype it, but it's still the go-to for reliable performance and durability over time. It actually gets BETTER the MORE you use it... Weird!

Bob Diamond

Wednesday 10th of January 2018

I am trying to decide which of these 2 machines would be best to do prototyping of machined aluminum parts.

Sam Westin

Thursday 11th of January 2018

Bob - is there a specific prototype material you need to use? If the print material is not important, I'd lean towards the Formlabs Form 2 if you are looking for small batch precision. If you need to pump out lots of prototypes quickly (precision is less important, but time is of the essence) than the Ultimaker will probably be best.