- How to Remove 3D Print From Bed - May 31, 2022

- Autocad vs Inventor: Which Software is The Best? - April 5, 2022

- Autocad vs Revit [2022]: Which Is The Right Choice? - March 31, 2022

3D printing has a language of its own, meant to convey the specialty tools, materials, and processes that are unique to its world. It’s a great way to explain details that don’t have an equivalent word or phrase in common usage, but it’s also confusing if you’re new to any of it.

Fortunately, we’ve put together a handy guide for you to use, whether you’re trying to wade your way through a sea of internet tutorials or writing your own instructions for others. Check out our categories below for any help or inspiration you might need.

Table of Contents

Parts

Extruder

A lot of 3D printer users consider the extruder the most important part of their setup, and with good reason. The extruder is where the material is fed into, heated up, and moved within the X, Y, and Z axes to print the layers of your object.

They are heat sensitive, requiring both a minimum temperature to keep the material flowing smoothly and maximum temperature to stop from burning the material or overheating themselves.

Within the whole of a 3D printer, the extruders are often identified by how many are attached to the frame. Single extruder printers are the most common; they have one extruder and usually work with only one color or type of material at a time.

Double extruders have two, and on the rare occasion, you will see some of the larger models have triple extruders. The extruders can work independently of each other or in concert.

X, Y, and Z axes

These are the planes of space that your 3D design will occupy. The X axis is the side-to-side, the Y-axis is the up-and-down, and the Z-axis is the depth. If you’re having a traumatic flashback to high school geometry class, don’t worry, you’ll have plenty of help deciding the measurements during your design phase.

The axes on the 3D printer are encompassed by the area that the extruder nozzle can reach to print, limited by the printing bed’s dimensions and the maneuverability of the equipment that moves the extruder along these axes. Your extruder moves through these via motors in the nozzle and extendable arms that are attached to the printer frame. It’s really fun to watch!

Printer Bed

This is an area of your 3D printer you will need to maintain especially well because this is the area that will be the literal foundation of your prints. The printer bed is where the extruder anchors the first layer of the filament to establish the base shape of the object. It’s a flat plane at the bottom of the frame, with the extruder posed above it. Most are adjustable, and that is a crucial aspect of printing.

If your print bed is not flush, your objects will start crooked, and there’s not much you can do besides start over. All 3D printers come with instructions on how to level the printer bed for your initial build; some have auto leveling capabilities that mean you don’t have to mess with it between prints. But, we do have experience with those you have to constantly adjust, especially print beds that come from cheap DIY printer kits.

A good print bed is also key to the stability of the whole printer, and a wobbly printer bed can knock everything out of whack. Its temperature control and grip surface are key to your final project as well; the wrong temperature and/or surface area means you’ll be wrestling your object off the print bed and stand a greater chance of damaging it and your project. Choose your printer bed wisely.

Process

- FFF. This is an acronym that means “fused filament fabrication,” which describes the 3D printing process because the material (or filament) is melted enough to be manipulated and stick together for built layering onto a base. Fused filament fabrication is the proprietary phrase for it, from the company that invented it (Stratasys Inc.) Stratasys originally trademarked “fused deposit modeling,” but switched to a different phrase when 3D printing became more mainstream so users could discuss the process without worrying about legal infringement issues.

- FDM. This acronym means “fused deposit modeling,” which is the same process as FFF. The only differences are that this phrase is not copyrighted, so 3D printer enthusiasts can use it for anything. It covers the same exact ground as FFF, so remember those can be used interchangeably in whatever instructional materials you may access.

- Post processing. As mentioned in the printer bed entry, you’re not done 3D printing once your extruder has stopped. After the object is done being printed, you have to get it off the printer bed without damaging it. For quality printers, this is usually as easy as letting the object cool for a time – either on its own or with the help of a fan, whichever will work with your time and patience. Some objects, or printer beds themselves, require a little more effort in the form of specialty scraper blades. Those, obviously, require very careful precision to keep from scratching the printer bed, the object, or yourself (gloves are for sure recommended). Once you’ve taken the object off the printer bed, you can add more finishing touches such as varnishes, further sculpting, or any details you weren’t able to print.

Software

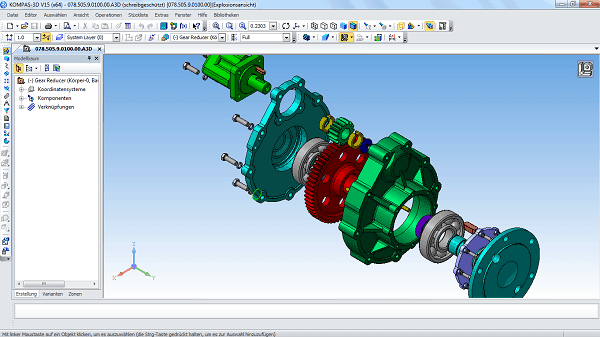

CAD

Short for computer-aided drafting, CAD is a catch-all term for the software you’ll be using to create your 3D printing designs. There are a lot of options out there. Many of them come from programs that were originally designed for 2D drafting needs such as architecture and have added 3D components as those computer capabilities have come online. AutoCAD is the most famous of these and has become an industry standard for anyone who wants to learn to draft in a professional setting.

There are plenty of other CAD programs that have sprung up especially for 3D modeling and printing as those have grown into their own processes. And if you’re not planning on 3D printing for your livelihood, don’t worry, because different CAD software has learning curves that vary as much as 3D printers themselves.

You also don’t have to drop a lot of money for a CAD subscription, either, and some printers come with their own programs that are just as good as any you can get independently. Just be honest with yourself about your skill level, and you’ll find the perfect software to get you using CAD in no time.

Open Source

If you’re familiar with other types of computer jargon, chances are you know that “open source” means someone has shared their code for free on the internet so anyone who wants to use it can and can make modifications to their heart’s content.

3D printing lends itself to this type of software because of its DIY fan base, so if you’re struggling with any company software, check out open source options. Not only are they free, but their transparency helps users understand the process, and see where they can individualize it.

STL Files

This is the extension for 3D printing design files. It’s an abbreviation for “stereolithography,” and that’s because it’s a type of computer-aided drafting that uses triangles to build the 3D forms.

First used in the AutoCAD system, it’s become standard on almost all 3D printers, and if you need to, you can convert other CAD file types to STL easily with software available for free or low cost on the internet.

Materials

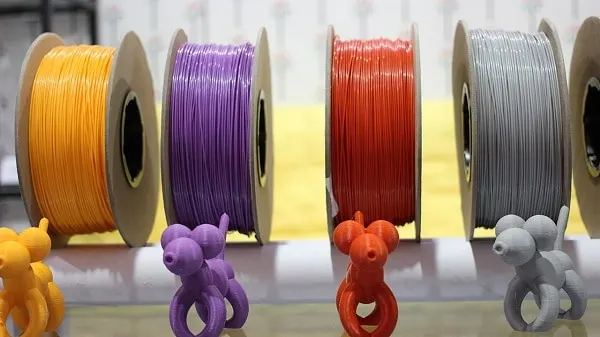

Filament

This is the stuff that you will print with. It’s a thread wound from some sort of thermoplastic (sometimes with other materials mixed in), stored on a spool. The spool is fitted to the printer so that the thermoplastic thread – the filament – is fed through the extruder, which heats up the filament and basically weaves it into your finished object layer by layer. If you’ve ever watched a sewing machine at work, the process is about the same, and the 3D printer filament plays the same role as the thread.

There are a lot of varieties of a filament to choose from, depending on your own skill level, your printer’s capacities, your wanted finish and hold, and lots of other factors you should consider before choosing one:

-

PLA. The most common type of 3D printing filament, PLA stands for polylactic acid. It’s a thermoplastic made from corn starch or sugar cane, which makes it non-toxic and biodegradable. For 3D printing, it’s stretched into filament thread and wound onto spools for easy storage. It comes in a wide variety of colors, and you can find it mixed with a lot of other materials as well; it makes a great base filament. Its relatively low print temperature makes it easy to print with since it has a much smaller chance of clogging or burning in the extruder nozzle. It also makes a smooth surface finish for your 3D printed objects, giving a level of surface detail beyond what other common filaments can achieve. It comes in two diameters: 1.75 mm, and 2.85 mm.

-

ABS. This stands for acrylonitrile butadiene styrene and is another thermoplastic that is created like PLA but uses a different kind of plastic – ABS filament uses the same kind as Lego bricks and is engineered for strength. Its combination of Acrylonitrile, Butadiene and Styrene polymers makes it shatterproof, scratch resistant, lightweight, and affordable, and its relatively low melting point makes it good for home 3D printing. However, it doesn’t have the detailed ability of PLA, it gives off a bad smell when it prints, and it needs a heated printer bed. You have been warned.

-

PETG. This is the acronym for Polyethylene Terephthalate Glycol-modified, a filament that is gaining traction in the 3D printing world for its properties. Although its makeup means it’s only available in clear and is not able to be color modified, it outscores PLA in durability. It’s also safe to sterilize and use for food. It’s not biodegradable, but you can recycle it by melting it down and turning it back into filaments (or other plastic materials). PETG doesn’t require a heated bed to work with, but it does perform better with one, and it’s soluble in acetone.

-

Eutectic Metal. This is a type of metal that is mixed in a specific way so that it has a lower melting point than its original form. This is how metals are mixed into filaments suitable for 3D printing; if you had to run your 3D printer at the temperature it takes to melt pure iron, for example, you would burn up all of your equipment before you got anywhere. The use of eutectic metal in 3D printing filaments gives users access to the metal’s general qualities while making it easier to work with.

-

HDPE. This stands for high-density polyethylene, which is the dense kind of plastic used to make plastic bottles. It’s used in 3D printing because it’s easy to dye and mold, and it’s also useful for printing supports because it’s soluble in limonene. So if you print the majority of your object in ABS or PLA and your supports in HDPE, you can dissolve the supports without doing anything to the rest of your material. It’s a great filament for designs that have a lot of details that are spaced out or overhanging other areas; you can basically defy gravity once your print job cools.

Going cold into 3D printing can be intimidating, but don’t let all the acronyms and formal terms scare you off. Words are powerful, and being able to label something gives you a better understanding of how it works, especially specialty information that can’t be translated any other way.

Learning them will give you power over what you want to do as you find more ways to improve your creation process. With a little bit of study, you’ll be able to navigate your way through whatever you need to do. Use our guide to translate what you want to do into actual processes and soon you’ll be able to hold the proof of your blossoming knowledge in your hand.