- How to Remove 3D Print From Bed - May 31, 2022

- Autocad vs Inventor: Which Software is The Best? - April 5, 2022

- Autocad vs Revit [2022]: Which Is The Right Choice? - March 31, 2022

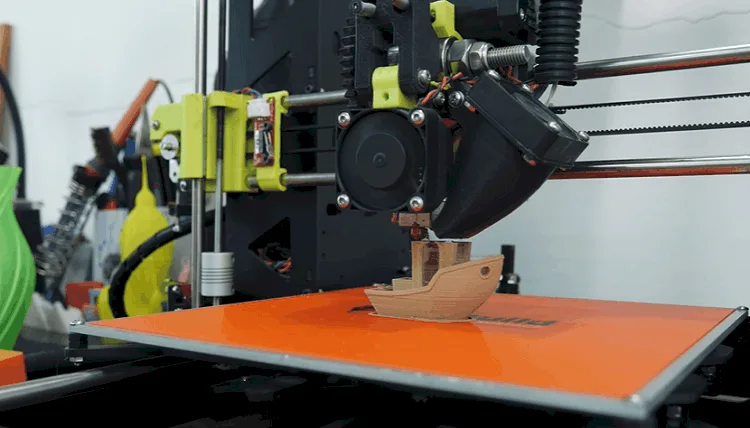

There’s no better example of 3D printing’s innovation than its use of wood. At first glance, it seems incompatible with the basic process — instead of melting into pliable material when heated, it disintegrates into a straight burn, and it lacks the homogeneous structure that makes other 3D materials like plastics consistent in their structural strength.

But 3D printing enthusiasts see new potential in wood as a natural, unique material, especially as the sector searches for more ways to become eco-friendly.

In this article, we’ll first explain why you should consider 3D printing with wood. It’s not just for the novel experience (although that’s definitely a fun reason!). 3D printing with wood can provide one-of-a-kind visuals and structure to your projects, and using a natural-based material, can also help you reduce your 3D printing waste.

Then we’ll tell you about the two different types of wood used in 3D printing. One is a more traditional blending technique that 3D printing uses with other types of non-pliable material like stone and metals, and the other is a newer development that is able to make wood by itself into filaments.

Most wood PLA in the market have a problem of jamming, but no more with our filament thanks to the patented Jam-Free foaming technology. It also dramatically improves the heat stability of our wood mimic PLA filaments.

We’ll also give you tips and tricks on how to 3D print with wood. Both types of wood-based materials require specific considerations, settings, and equipment in order to work their best. We’ll let you in on the quirks of the 3D printing process with wood and alert you on what to look out for in case anything starts to go wrong.

Finally, we’ll end the article with frequently asked questions about 3D printing with wood. This will include where to find the materials and tools we talk about in the rest of the article. Although wood is a relatively new material to work with, there are already a lot of machines, tools, and filaments to help you become an expert in no time.

Table of Contents

Why You Should 3D Print with Wood

Wood is a great material for your 3D printing projects. It projects an old-school craft look without you needing to learn a whole new skill, and it adds a great natural touch to both your objects and the waste that comes from making them. Here are our favorite reasons to 3D print with wood.

Variety

If you can name a wood, chances are there’s probably a way to 3D print it. Because most wooden 3D printing filaments are mixed with PLA, their consistency remains the same.

This makes it easy for filament makers to add pieces of whatever wood they want without having to go through a different process for each, so there’s a wide variety of wood-based 3D printing materials out there. Everything from decorative ebony and olive, to more utilitarian birch, cedar, and pine, to exotic bamboo and coconut wood is available in some form to 3D print.

Customizable Finishing

Beyond the variety of the filaments themselves, 3D printing with wood also allows for as much end customization as actual woodwork and carving.

Your 3D printed object retains the pliable characteristics of wood, so unlike full-plastic products, it’s ripe for sanding down and painting whatever colors you want, or adding a sealant to preserve its natural finish, or leaving as-is for a rustic touch. The choices are as endless as your imagination, and you can always make post-production changes that the surfaces of PLA and ABS, for example, don’t allow.

Easy to Work With

Like all specialty filaments, wood does require a few adjustments to your 3D printing equipment (as we’ll tell you about in detail below). But unlike many others, wood’s requirements can be met easily with equipment at hand and don’t require a bevy of specialized add-ons.

Wood’s pliant nature mixed with much more common filaments such as PLA also gives you a smooth printing experience. Plus, wood filament’s finish is great at hiding layer ridges that stand out so distinctly in other materials, so it’s easy to experiment with the best layer thickness without any obvious marks on your finished objects. (And they can always be sanded over for an even more smooth surface.)

Biofriendly

Because wood 3D printing filaments are composed at least partially of a natural material, many of them are recyclable or biodegradable. This is a great way to add a more environmental-conscious angle to your 3D printing and avoid adding to the growing heap of non-recyclable plastic waste that comes from the industry each year.

Some brands of wooden 3D printing filament are even wound onto cardboard spools instead of the typical plastic packaging, which means everything you get from them is recyclable.

Be sure to read the directions on each type of wooden filament you get; some you can recycle without any processing, but some require soaking in water or other primary steps before they can be broken down, so make sure you know what your specific wooden filament requires before you dispose of it.

Longevity of Finished Product

PLA itself can last up to fifteen years as a 3D printed object; when wood fiber is mixed into it, that can extend to several decades. This is helped along even further by sealant and other post-processing typical to complete wooden objects.

Types of Wood 3D Printing Filaments

3D printing with wood has come a long way since its inception around 2012. The first wood filaments were made by mixing pieces of sawdust into the standard plastic filament PLA.

However, those produced subpar finishes that looked much more like cardboard than actual woodgrain. Since then, filament producers have succeeded in bringing real wood qualities to prints by mixing fibers from pieces of the wood itself instead of its byproducts.

There are two ways of making wood particles into filaments, one that has been around since the sawdust days and utilizes the same process, and another that is just developing as a unique process all its own.

Blending Wood Particles into PLA

This is the original process that started 3D printers’ experimentation with wood filaments. Its goal is mainly to recreate the look and feel (and sometimes smell!) of wood while keeping the melting and molding properties of 3D printing so that the printing process is not radically altered and can be incorporated without needing excess training or equipment.

This means that the wood is broken up into small enough pieces to blend into filaments of polylactic acid, or PLA — one of the most common 3D filaments available.

In fact, wood filaments produced like this are actually only about 30% true wood pieces and about 70% PLA. (Interestingly enough, this does not alter the ability to recycle these wood filaments since PLA is also recyclable when treated for such.)

Winding Wood Particles with Natural Binders

In 2021, several companies have announced a new way of producing 3D wood filaments that excludes PLA entirely. They utilize lignin, a tree’s natural binding agent, and wood waste material for a plastic-free printing experience that can be completely smooth or printed with grainlines for an all-natural look.

Right now, this process is being tested by several furniture companies as ways to save forestation. But keep an eye out for wood and lignin filaments to come onto the general market for your own home 3D printing use in the next few years.

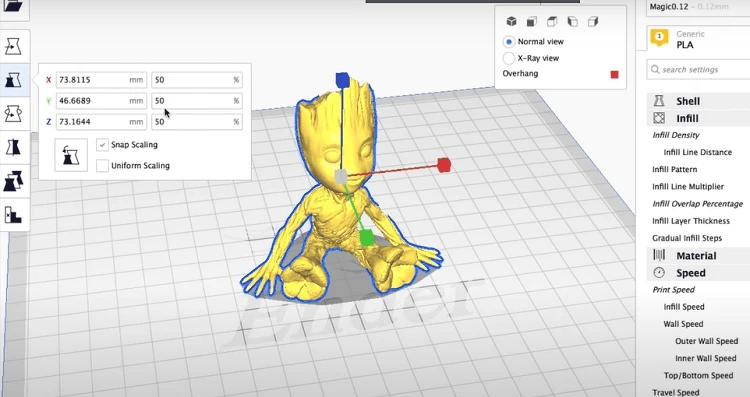

How to 3D Print with Wood

As we’ve mentioned, one big advantage to 3D printing with wood is that it’s an unusual material but doesn’t require special equipment. Here’s how to tweak your existing machine to best use wood filament for your 3D projects.

Lower the Print Temperature

Even if you’re working with a blend that’s majority PLA, you need to keep in mind that wood has a low burn point. This can be fun for varying the natural color of your print, with higher temperatures creating a darker wood pattern.

But when you’re new to 3D printing with wood, it’s best to stick within guidelines specified on your filament. Using any wood for 3D printing means you need to use a lower printer temperature than with non-wood materials to keep your print from catching on fire. This will generally range from about 170 to 220 degrees Celsius, depending on how much PLA your filament contains.

Keep the Extruder Nozzle Clear

This is another necessity for fire safety while 3D printing with wood. It’s also good practice to keep your filament flowing smoothly for the integrity of your design. Since wood can be slightly chunkier to work with than pure plastic, we recommend getting an extruder nozzle that’s wider than the standard 0.4 millimeters.

Those can be found separately from a new full machine, so they’re a cheap upgrade. Plus, the wider nozzle is easier to clean off previous gunk to keep your wood moving.

Increase Printing Speed

If keeping your extruder nozzle clean doesn’t seem to keep your wood prints from stalling out, use a higher print speed. Wood filament dries quickly compared to other materials, so moving it faster through the printer’s insides keeps it in the liquid state best suited to extrusion.

Use an Adhesive Print Bed

A stable foundation is vital for 3D printing with wood. The makeup of the filament creates pieces that slide around a lot, which is fatal to the process of adding layers on top of each other.

You can buy heating bed sheets that provide a sticky printing surface, or you can simply use painter’s tape or a glue stick to mimic those products. Either method will go a long way towards keeping your wood print steady as it’s built.

Keep Fine-Grain Sandpaper at Hand

3D printing with wood is great for a project that needs to look cohesive and continuous. That doesn’t always go with the layering effect inherent in the 3D printing process, but the good news is that you can easily hide some of the smaller missteps when you use wood filament.

Fine-grain sandpaper helps you shave off blemishes on your finished object’s surface, blend together any layering marks you want to hide, and even do a little bit more sculpting if an area doesn’t come out exactly as you want it. As with any wood project, make sure you only go to harsher grains of sandpaper if the finer stuff doesn’t work first.

If you're a fan of the smell of fresh cut lumber, but fear the sound of saws and drills, then ColorFabb Woodfill filament is perfect for you! 70% PLA and 30% recycled wood fibers, this specialty filament has a finish that rivals finely carved and sanded natural wood pieces.

Troubleshooting 3D Printing with Wood

There are several things to look out for when you’re using wood filament to 3D print. Most of these can be easily solved with minor adjustments to your process.

Brittle Filament

While wood is a strong building material on its own, blending it with PLA has the unfortunate side effect of making the whole filament take on the brittle properties of its plastic majority.

That means wood filament should not be used in designs that require heavy layers to be held up by lower ones. If you follow guidelines on how to design and avoid cave-ins for PLA, your wood filament objects will also stay intact.

Flammability

It’s worth repeating that wood filament is liable to catch on fire if you get it too hot. Fire safety is, of course, necessary to practice no matter how you’re 3D printing, but using wood in these conditions requires an especially close eye on your material to make sure it does not pose a risk to yourself or your work.

Storage is important, too; make sure your wood filament is stored in sealed containers kept in a cool, dark place to avoid any sun or moisture damage.

Stringy Printing

The wood fiber pieces mixed in with PLA are naturally long and stringy. This can create areas of printing with strings of material dangling into what is supposed to be empty areas of your design.

Unfortunately, there’s not much you can do during your printing process with wood to prevent this, but the strings are much lighter and weaker than your printing lines and do not adhere to your object very tightly.

That means it’s easy to scrape them off during post-processing to clean your finished project. (We recommend doing this as a first step after the object is done printing, so the strings don’t solidify or interfere in any other post-printing finishes you want to apply.)

FAQs

Answer: Great news: none! 3D printing with wood does not require you to learn any new techniques to get started. Just design and print as you would with any other filament, keeping our tips and tricks in mind to get the best out of the wood.

Answer: Wooden filament in its most common form (mixed with PLA) is available from the vast majority of 3D printing filament retailers because it’s gotten much easier to make since its inception. Our favorite brands include Timberfill for its wide selection, Filamentive for its eco-friendly packaging, and SainSmart for its high percentage of wood fiber (40%) in the mix. We’re also excited about the pure wood filaments from Forst, but we’ll have to wait for those to come onto the consumer market.

Answer: This depends almost entirely on your personal preference. Wood makes a solid, long-lasting 3D printed object that can be customized in an infinite number of ways post-process. The only thing you need to consider is that the PLA in the mix makes the object a bit brittle while still printing, so anything that requires delicate latticing between heavy layers should be done with something else.

Answer: This depends almost entirely on your personal preference. Wood makes a solid, long-lasting 3D printed object that can be customized in an infinite number of ways post-process. The only thing you need to consider is that the PLA in the mix makes the object a bit brittle while still printing, so anything that requires delicate latticing between heavy layers should be done with something else.