- How to Remove 3D Print From Bed - May 31, 2022

- Autocad vs Inventor: Which Software is The Best? - April 5, 2022

- Autocad vs Revit [2022]: Which Is The Right Choice? - March 31, 2022

So you’re looking for a 3D printing material that is strong enough to build objects that endure punishing tests on a regular basis, yet precise enough to make intricate, one of a kind jewelry. You’ve tried a few different thermoplastic combinations but just aren’t getting the exact combination of qualities you need for your wide range of projects.

Where do you find such a combination of strength and delicacy? Look no further than 3D printing with titanium, a process that infuses all the metal’s strength into a printable alloy that’s great for virtually all of your small to medium sized object needs.

Table of Contents

What is Titanium 3D Printing?

Titanium is a silver transitional metal, which means it’s an element that has a partially-filled d subshell. Translation? Its outermost electron orbit isn’t filled to capacity, so it can bond with other elements by sharing their electrons. That means it plays well with others, and with certain ions, it can get an electrical charge, which is great for titatnium 3d printing.

It’s got low density and high strength, which means it can hold a lot without getting bogged down in its own weight, and it’s resistant to corrosion in salt water and chlorine, among others. Also, its lustrous finish makes it shiny. We always count that as a plus.

How Do You 3D Print With Titanium?

For 3D printing, titanium requires more consideration and preparation than other metal alloys because of its strength and other physical properties. While you can spin other metals onto spools of filaments and use them more or less like traditional 3D printing materials such as PLA or ABS, titanium requires different 3D printing equipment. Specifically, titanium requires lasers.

Yes, you read that right: titanium is metal in more than the literal sense. To wrangle titanium 3D printing projects, you have to utilize an additive metal fabrication process called direct metal sintering.

The design process is no different than with your usual computer-aided drafting program. In fact, you can use whatever 3D design program suits your fancy as long as it’s compatible with the titanium 3D printer – and most of them are. Most 3D titanium printers accept the same design file extensions as standard 3D printers, so the only part you have to worry about here is making your design fit your imagination.

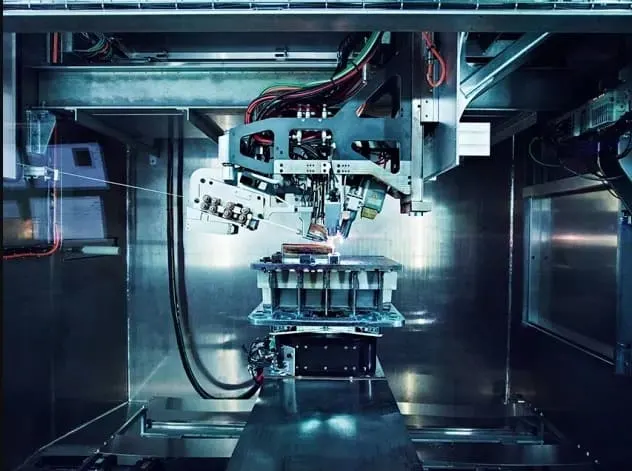

But here’s where 3D printing veers down a different path than your traditional thermoplastic creations. Because of its properties, titanium 3D printing needs a specific type of printer called a DMLS machine. Although this type of machine does the same kind of work and produces the same kind of 3D product as fused filament fabrication and fused deposition modeling, it gets there in a different way that requires the design to be uploaded into the machine itself instead of hooking the machine to your computer to transfer the file.

After you’ve gotten your design set and loaded into the DMLS machine, the machine will use a powerful optic laser to do the building. This laser fires into a special chamber on the DMLS machine that. Within this chamber is a platform that dispenses the building material – in this case, titanium powder – into layers; basically, the laser melts the powder into a liquid that is then shaped into the layers by the blade. Sound complicated? It is one of the more involved types of additive fabrication processes, but the good news is, once you’ve finalized the design and fed it into the machine, the DMLS does all the rest.

Some 3D titanium printers use a variation on the DMLS process called electron beam transfer (EBM), which is very similar but uses a concentrated beam of electrons instead of a laser. Both processes use a localized melting process (that’s what the focused energy of the lasers and/or electrons are for) that takes the titanium from a powder to a solid that can be manipulated into layers that are easily shaped and adhered to each other. Science!

What kind of equipment do you need to 3D print with titanium?

Unlike a few other metal alloys, titanium can’t be used as a regular 3D printing filament, and that means you need a specific type of printer in order to utilize its 3D printing potential. You need a DMLS machine in order to perform the specific type of laser-tastic process we talk about above. And did we mention you also need a laser? That will be included in the DMLS machine, but we’ll use any excuse to talk about lasers.

The DMLS machine will also include a build chamber that is specially calibrated to handle the DMLS process, which means it has to be tough enough to contain extremely concentrated beams of energy. Again, this is pretty much an automatic given with any DMLS machine you’ll purchase, but check on the strength of the build chamber before you buy just in case.

One more piece of special equipment that you’ll need for titanium 3D printing is the titanium itself. Instead of buying string-like filament by the spool, you’ll be buying titanium that’s been ground into a fine powder so the DMLS machine can do its thing. This is easy to find with DMLS equipment, and if you want to use something besides titanium, you can find other metal alloys in the same DMLS ready medium.

What Are The Pros of 3D Printing With Titanium?

3D printing with titanium has a lot of good features to take advantage of. Here are a few key ones to remember:

- All in one process. Although titanium 3D printing does require its own specific machine, a DMLS machine does everything except design your product for you. That makes 3D printing with titanium ideal for producing prototypes and test parts, and if you’ve spent any time trying to make things work, you know how much time prototyping and testing can save you in the long run. DMLS machines produce 3D printed objects without any special tooling requirements, so you don’t have to worry about additional equipment or processes when you’re getting your printing done. And that is not only a time saver but a sanity checks as well.

- Level of detail. The process of DMLS produces the best details you’ll ever get from 3D printing. The layers are easily arranged – the laser (or electron beam) cuts a much more precise line of material than traditional 3D printing extruders, so this makes it ideal for tiny details that require a lot of finesse. You can add flourishes to designs that would not have otherwise been able to support that level of structure. This is great news for industries that rely on small to medium sized parts to be readily available and accurate, like dental, medical, and aerospace constructions.

- Ease of producing prototypes. But you don’t have to be an astronaut to reap the benefits of 3D printing. If you need any sort of replication to try and tear to shreds, 3D printing with titanium makes that cost-effective and, dare we say, easy. You won’t be able to print on an industrial scale, but what you can print will be exactly what you need to see if anything needs adjusting before you print the real deal. This will save you so much time and money that you’ll wonder why you didn’t add this step to your routine earlier.

What Are The Cons of 3D Printing With Titanium?

Although it’s a great process that can benefit your 3D printing immensely, titanium 3D printing does not come without its drawbacks. We’re discussing them here so you can figure out if any of them override the good parts for you.

- Cost. We list this as a con for a fair number of 3D printers and new innovations in the field, but most of those are relative to each other. Generally, 3D printing is pretty cost inclusive. However, we need to emphasize that 3D printing with titanium is decisively not. When we say it’s expensive, we mean that a DMLS machine will cost you more than a mid-level car – starting at around $25,000 for a beginner. ‘That is objectively too much money for something you’re not sure you’ll need or like to use, so unless you are positive you are going to 3D print in titanium enough to justify this cash layout, think really hard about buying your own setup. Of course, the bright side to this is that DMLS machines are self-contained, which means once you buy the initial setup, you’re good until you need more titanium material to print with.

- Print size. One tradeoff for the exquisite details that you can get 3D printing with titanium is that you aren’t able to scale these to a bigger size. DMLS machines only have enough space to print small to medium sized objects, which is why they’re so great for parts that need precision. But if you’re looking to 3D print some massive structures, you’ll have better luck with more traditional printers that are specifically built with big printer beds.

- Z-axis mistakes. Because of how DMLS machines manipulate layers, it’s easier for mistakes to show up in the Z-axis than with traditional 3D printer extruders. The technology, although great at keeping attention to details on the Xs and Ys, is not refined enough to be perfect, and a little uncertainty on layer height movement is the most obvious way this manifests itself. However, this can be fixed by a careful design process and by keeping an eye on the DMLS machine as it prints; if you’re seeing something start to go bad, stop the 3D printer and readjust.

- No pause and save mechanics. The smarter class of traditional 3D printing extruders let you pause in the middle of your work, either voluntarily or not, and come back to the rest of it later in the same spot without you having to adjust much if anything. But again, those sweet lasers that let us geek out about how many wrinkles we can add to our timeless wizard 3D figurine, or how fine we can make the gears for a new dental drill, don’t have a pause mechanic that let you get your titanium 3D printing done in different chunks of time. Make sure your time and your power source are both spotless and able to go through the whole process you need for your object.

- Surface imperfections. Titanium is generally a smooth alloy to work with, but because DMLS machines print with such precision, it may be difficult to notice a tiny surface imperfection that will cause problems later on down the chain if you’re 3D printing titanium as the first step in a multistep manufacturing process. This doesn’t necessarily mean you have to reprint, though, especially if the imperfection is small enough in the area. You can just buff those out, we promise.

- File format conversion. While you can design your 3D printed object on any computer-aided drafting program you’re most comfortable with, DMLS machines do have to convert that file to its own extension, which is an extra step that may make you impatient but is necessary. And that also means you can’t make adjustments to the design file on the fly. A good piece of advice in general for 3D printing with titanium is to make sure you’re 100% positive of your design before you print. That will decrease the chances you’ll have to deal with the issues we talk about above.

What is the verdict on 3D metal printing with titanium?

If you can get past the enormous startup cost to buy your own DMLS machine, or if you’re able to rent time on someone else’s, titanium 3D printing has a lot of perks. They stem from the material itself – its strength, its luster, its ability to conduct electricity – and from the DMLS process, which uses a nontraditional extrusion method that lets you print excellent details.

If you’re in the business of manufacturing small to medium parts for delicate instruments, or if you are in an industry that relies heavily on prototyping, you should consider 3D printing with titanium alloy. The self-contained processes and level of work you can get from DMLS machines make it totally worth it if you’re in need of leveling up your 3D printer.

![How to Find the Best Titanium 3D Printer [2022]](https://total3dprinting.org/wp-content/uploads/2019/03/How-to-Find-the-Best-Titanium-3D-Printer.jpg.webp)