- How to Remove 3D Print From Bed - May 31, 2022

- Autocad vs Inventor: Which Software is The Best? - April 5, 2022

- Autocad vs Revit [2022]: Which Is The Right Choice? - March 31, 2022

If you’ve gotten bored with thermoplastics and are looking for a new way to experiment with your , filaments are a great direction to take.

These are filaments that mix pieces together with a more conventional such as so the can be manipulated like more flexible filaments despite its inherent rigidity. The is usually about 70% polymer to 30% fibers, and you can buy spools of just like any other on the market.

They’ve been around since 2012, beginning with polymers mixed with sawdust, but those resulted in products that looked more like cardboard, so the filaments quickly evolved.

Here’s a quick summary if you are in a hurry…

Table of Contents

The Best Wood Filaments for 3D Printing

- Timberfell – Best Premium Wood Filament

- Laywoo Filaments – Best Budget Wood Filament

- ColorFabb – Best Color Wood Filament

- MG Chemicals – Best Durable Wood Filament

- HatchBox – Best Fine Wood Filament

- EasyWood – Best Wood Filament for Different Wood Types

- AFINIA – Runner-Up

- Hestay – Runner-Up

- Torwell 3D – Runner-Up

- RS Pro – Runner-Up

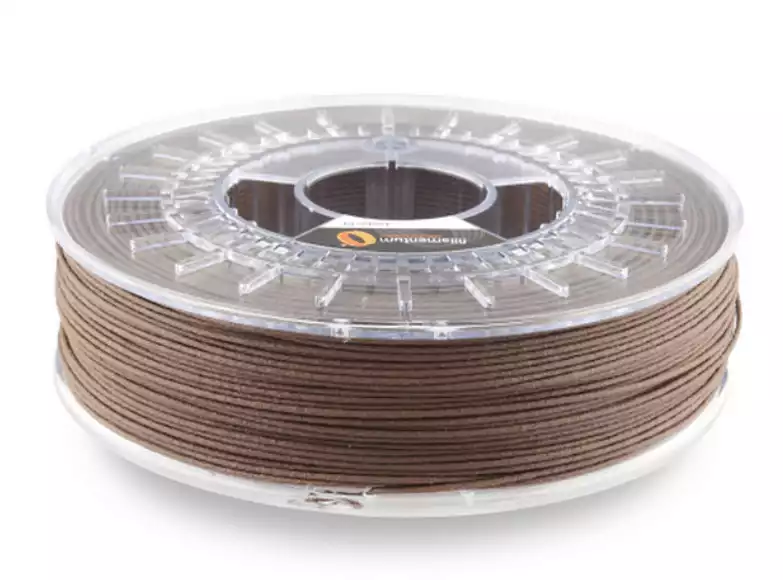

Timberfill is an exciting new filament from Fillamentum that is made from wood-based biodegradable material. Timberfill prints and functions very similar to PLA, but has the genuine look and feel of wood!

What are Wood Filaments?

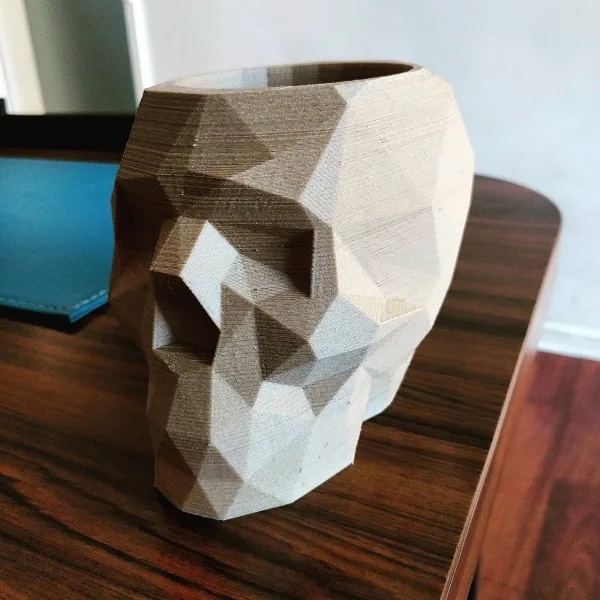

filaments give your finished object the look, feel, , and even smell of a carving, complete with the grain and fluctuations you see in the hearts of trees. They take on the properties of whatever you use as well, such as the extra sturdiness you may be looking for beyond .

One type of contains a piece of coconut mixed in with the , which gives the finished product a distinct look and that you won’t be able to get with .

If you don’t like the finish you end up with, it’s just as easy to stain your 3D with whatever varnish you want as it is to stain your coffee table, bookshelf, or any other object made of pure . You can also sand down rough edges or mistakes or carve finishing details with a knife or burning kit; the possibilities are vast and don’t end once you turn off your printer.

How to Work with Wood Filaments [3D Printing Wood]

However, is not for those who are new to . filaments are finicky to work with and require much more manipulation and monitoring than entry-level thermoplastics. A will reward you with beautiful, unique objects, but first, you have to learn how to treat them:

- Use a larger to . The recommended size is 0.3 mm or larger, which helps the dark chunks in the flow through without clogging up. This may result in larger layers than you want, but you can sand down the product until its finish is as smooth as you want, so don’t let that keep you from heeding this advice.

- Remove the from the printer when you’re not using it. The can burn if left unattended in a printer that hasn’t cooled down yet, or stopped for some reason, and this will result in a clogged with blackened, hardened . If you’ve already learned this lesson the hard way, run a cleaning through your . They’re easy to find and inexpensive, a must have if you’re going to work with . Just in case.

- Find the right temperature. A lot of enthusiasts manipulate the finish of their filaments by using a higher temperature than recommended for . The higher the temperature, the darker the , but that’s because the higher is essentially burning the as it goes through the . There’s a very fine line between a different finish and a burnt , so only attempt this if you have the time, patience, and knowledge to do it safely. And if you’re worried, at the recommended temperature, then paint the finished object with whatever color stain you want. No fire hazard necessary.

- Use fast printer speed and high layer heights. Yes, these steps will result in more wobble on the Z axis and chunkier layers than you might want, but they’ll keep your moving through the . Less time in the means less of a chance for the to ignite, and less of a chance you’ll have to clean up that mess. Just make sure your printer is secured for as little frame movement as possible, and sand down any layers that don’t meet your standards.

- Use higher retraction. filaments and are runnier than when they are flowing through the heated larger . This will lead to drag if you don’t adjust how fast the comes out of the , so make sure you adjust to the recommended retraction setting rather than leaving it as it was from working with the previous . Retraction speed and distance will both make a difference.

Types of Wood Filaments

Now that you know what to look for, let’s talk about the varieties of that are out there. There are three general varieties available:

- Regular woodfill is the basic variety that is polymer blended with pieces of traditional varieties of and such as oak, maple, or birch. It has the scent and visual properties of the dominant variety blended into it, and although it does smell burnt when you with it if you’ve got your temperature settings correct it will be a stable throughout the process.

- Bamboofill . This is a polymer blended with bamboo fibers, which is more sensitive to temperature and clog than standard woodfill . This means you’ll have to make sure you clean your thoroughly before and after every with bamboofill , and you won’t get as wide a color variety as with regular woodfill , but you’ll be rewarded with a smooth endowed with the flexibility of its blended .

- Corkfill is slightly porous and a much darker color than bamboofill or regular woodfill . It has the finicky properties of bamboofill while letting you something more lightweight and rigid at the same time.

Wood Filament Companies

Finally, it’s time to choose where you want to buy your woodfill for . There are a number of companies that put out quality for (approved ). Here are our favorites:

Timberfill . These woodfill filaments are made of 100% biodegradable sources, which means you’re doing something good for the planet while leveling up your hobby. Timberfill also gives you a relatively large selection of colors. You can pick from cinnamon, light tone, rosewood, and champagne, all of which display natural variations that you can mix and match to your content. This is more expensive than most of the others you can find at $51 per on MatterHackers here , but its variations and environmental friendliness makes it worth it.

Timberfill is an exciting new from Fillamentum that is made from -based biodegradable . Timberfill prints and functions very similar to PLA, but has the genuine look and feel of !

Timberfill is an exciting new filament from Fillamentum that is made from wood-based biodegradable material. Timberfill prints and functions very similar to PLA, but has the genuine look and feel of wood!

Laywoo Filaments. The OG of woodfill, literally – this German company’s founder Kai Parthy invented wood filament for 3D printing in 2013. Lay Filaments sells a light cherry type, which means you can experiment with temperatures to create different colored finishes. It also sells a flexible wood filament that’s one of a kind and super useful for those who are just starting out with wood filaments since there’s more give to work with. You can find these filaments on MatterHackers here for around $35, but realize that they’re sold in bundles that are less than standardized full spools. You’ll get about 100 grams from most sellers, so do some math to figure out if that will really be the best bet for you.

At print temperature LAYWOO-D3 is less viscous than PLA or ABS, a few extra steps can help improve your printing experience: Adding extra extrusion to the beginning of your print will help prevent dry extrusion during the initial layers. Increasing the retraction setting of your part during slicing will reduce 'leakage' while the hotend is moving between sections (especially over open areas).

ColorFabb. This company based in the Netherlands offers standard woodfill, bamboofill, and corkfill; ColorFab’s strength is its variety on offer. One spool of woodfill from them costs $49.99 at MatterHackers here, but the quality you’ll get makes it worth it. However, keep in mind that ColorFab’s woodfill filaments are not for beginners. Their high quality and relative expense mean you want to be sure you know how to deal with the unique problems of woodfill before you buy any.

The colorFabb line of specialty 3D printing filaments gives any enthusiast great options for adding variety to their usual prints. These 3D printing filaments are infused with materials in addition to PLA, such as steel, copper, bronze and brass dust, giving your prints the ability to be polished to look like real metal.

MG Chemicals. These guys use poplar for the wood particles in their wood filaments, about 25% mixed with PLA (a hybrid wood PLA). Poplar wood particles are larger than other wood filaments, so make sure you have a nozzle that can open to 0.4 mm to prevent any clogging. If you burn up any filament in the extruder, it will be harder than usual to scrape out because of the size of the popular pieces. This is a great woodfill to start with. It’s as sturdy as any other standard wood filament while being as much of a bargain as its thermoplastic cousins ($31.45 per spool), and MG Chemical gives you free shipping if you buy a few spools at once. So stock up on whatever filament you need, and throw in a wood filament spool for fun to see how it works for you. Check out the latest prices on Amazon.

HatchBox. This company has quality control on lock. That means their wood filaments are less likely to clog your extruder because they have gotten the tolerance down to +/- 0.01 mm from the expected diameter; so the filament you buy will all be within a hundredth of a millimeter of the advertised diameter. This is crazy good compared to the standard +/- 0.05 mm tolerance. So if you’re looking for a material that can be more forgiving of your mistakes because they don’t tolerate their own, try out Hatchbox wood filament. Their wood filaments go for $34.99 per spool (check latest prices on Amazon here).

Read our full HatchBox Review here.

EasyWood. This company has even more options, in willow, pine, olive, ebony, cedar, birch, and even coconut. These boast a 40% wood particle content, and if you can’t decide which one you want to start with, there’s a sample pack you can buy for $18.01. Full spools of EasyWood varieties are $31.13 (check latest on Amazon here), making them a good bargain for any projects you want to experiment with.

AFINIA. These guys offer a major bargain wood filament. It costs $15.99 per spool, and it’s available at the Home Depot, so if you’re looking to get started with wood 3D printing right away, you totally can. It may not have the array of variations some of these other brands do, but it does have great customer reviews, and it comes in 200 g spools, so we’re naming this one best value.

Hestay. This company only has one finish of wood filament, but it comes in three different diameters: 1.75 mm, 2,85 mm, or 3.0 mm. While 1.75 mm is the recommended diameter for beginners, if you’re brave and/ or know exactly what you’re doing, experimenting with larger filament diameters can give you some unique results. Just make sure you have an extruder that can handle the larger ones if that’s what you get. These spools are $42.29 and come from the Netherlands.

Torwell 3D. Want to save the planet while 3D printing? Torwell uses recycled wood as 35% of its blended filaments. The other 65% is high-grade PLA, and that ratio results in an easy, smooth 3D printing process. You can choose either 1.75 mm or 3.00 mm with the confidence that both will act the same for you. This company is based in Australia, so if you don’t live near that part of the world you may have to wait out a slightly longer than average shipping time, but according to their customer reviews, Torwell works hard to make sure that doesn’t become a major issue. Just remember they can’t make the clocks go any slower, order in plenty of time for your project needs, and enjoy their great customer service if you need anything from them.

RS Pro. These folks sell a filament in “tropical wood” color. What does this mean? A small but noticeable spectrum of variation speckles that translate from the spool to your finished object without detracting from the overall shade. If you can’t picture that, think of how tree bark is almost never all one uniform color; this woodfill reflects that beautifully. It’s $20.75 per spool and acts like your standard other wood blend filaments, so check out this variety for subtle depth to your finished color.

Frequently Asked Questions about Wood Filaments

Can you use wood filament in a 3d printer?

Yes! Using wood filament in a 3d printer is becoming an increasingly common tactic as people come to appreciate the extra sturdiness and aesthetic that comes with using bamboo, timber, birch, coconut, or other woods in your 3d printing.

What temperature should wood filament be?

Wood filaments should be at a higher temperature than normal for 3d printing – The higher the temperature, the darker your wood will be. You can always play it safe and print at a regular temperature and then stain the wood filament print to your liking.

Is wood filament actually wood?

Wood filament is not entirely wood. It is actually a mix that combines PLA with wood powders like cork, and wood dust. Each filament will have it’s own specifications, but most wood filaments sit around 30% wood.

Final Thoughts on Wood 3D Printers

There you have it – all about 3D printing material with woodfill blends. Although this is a tricky filament to get right, it’s well worth it to master.

You’ll be rewarded with finished projects that look like you spent years learning how to carve wood; and when it’s finished, the 3D wood filament is actually very forgiving, since you can sand it and paint it with whatever kind of varnish you like. So get to know your printer temperatures and try out this unexpected yet easy blended filament.

Timberfill is an exciting new filament from Fillamentum that is made from wood-based biodegradable material. Timberfill prints and functions very similar to PLA, but has the genuine look and feel of wood!

![The Best Wood Filament for 3D Printing [2022]](https://total3dprinting.org/wp-content/uploads/2019/03/The-Best-Wood-Filament-for-3D-Printing.jpg.webp)