- Creality Ender vs Anet A8 [2022]: Which is Better? - April 14, 2022

- TEVO Tornado Review [2022] All You Need To Know - April 6, 2022

- Anet A6 Review [2022 UPDATED Version] - April 5, 2022

You’ve got your design perfected and your dimensions on point. You’ve beasted your computer-aided drafting program and your 3D model is perfection. The only decision left is when to hit print. Right?

Not quite! Before you continue, make sure you take the time to figure out what materials and filaments you want to use. There’s a huge variety, and their properties can drastically change both the art and the utility of your piece. Let us guide you through the options so you can figure out that final important detail.

What’s the Difference Between 3D Printing Material vs Filament?

First of all, let’s distinguish between material and 3D printer filament as they apply to 3D printing. Materials are the general properties of what you are using to print: for instance, plastic, wood, or nylon filament (yep, you can 3D print with wood filament!).

Filaments are the thread-like pieces of those materials that are wound on spools and pushed through your 3D printer’s heating mechanism to weave your design.

How do I figure out the best material and filament for my needs?

The majority of materials for 3D printing are thermoplastics, especially if you are looking for beginner materials. These materials are designed to melt instead of burn when they’re heated, and they come in two sizes, 1.75 millimeter and 3 millimeter. Those measurements refer to the width of the filament.

Check whatever 3D printer you’re using to see which one you need; the standard for basic printers is 1.75, but it’s always good to double check. Filaments are sold by weight ranging from 0.5 to 2 kilograms, which tells you how much filament you’re getting on each spool, and they come in a wide variety of colors.

If you have a dual extruder 3D printer, meaning your printer has two nozzles that deposit 3D Printer filament onto the printing surface, you can do some amazing things with filament color mixing.

But you can also find composite filaments, which have bits of other materials blended into the mix. This is where you can find wood filament blends, as well as stone and metal varieties.

These filaments have elements of the non-plastic materials that are blending into them, which means they will behave a little differently than thermoplastics on the final product but still print the same.

So if you use a carbon fiber composite filament, for instance, your finished product will gain some of the strength of carbon without you having to adjust your printing process.

Be aware that composite filaments are more expensive than thermoplastics because of their composition, which takes the added materials’ cost into account.

Another option is resin-based printing, which does not use fused filament fabrication or fused deposition modeling printers but stereolithography equipment.

This tends to be a more advanced method of 3D printing, but if you’re on that level, keep that in mind when looking for the perfect type of filament for your pieces. These types of printers are the first type of 3D printing technology developed, and they produce very detailed high-resolution prints.

They began as professional grade equipment and are priced as such, but in the last few years more affordable options have been developed for artists and hobbies. If you’re into this area of 3D printing, you choose the kind of resin you want to use instead of filament.

Stereolithography uses ultraviolet lasers to trace a shape on UV-sensitive resin. The resin that’s exposed to the laser hardens to form the 3D printed object.

Another type is digital light processing, which has the same process except with a projector that uses visible light instead of UV light. Using either of these methods means you’re choosing what kind of resin to pour into the printer’s vat or tray.

They come in 500 milliliter or 1 liter bottles, and the prices start at about $100 per liter. There are special blends made for strength, flexibility, or other properties, and you’re generally limited to gray, black, white, or clear unless you’re willing to dig and/or pay more money.

What is the Best 3D Printing Filament for You?

Now that we’ve gotten through the basics of 3D printing materials and filaments, it’s time to get specific about your options. We’ve divided these into sub-categories that let you know what each kind does best and how much it costs so you know at a glance what you need.

Standard Filament

These are your go-to filaments. Some of them will come with your new 3D printer, others you will want to use on a daily basis. They have a range of attributes from strength, to durability, to flexible or even transparent. They can be used by a range of experience levels and will come in just about every color you can imagine.

PLA – Polylactic Acid

PLA is the most common material used in 3D printing. It is the default option for many printers, and you will typically find a spool of PLA in the box when you first get a new 3D printer. It’s an inexpensive plastic that is made from renewable products (cornstarch-based plastic).

PLA is one of the easiest filaments to use. It is a great option for all experience levels when it comes to 3D printing. Some benefits of PLA are that it’s an odorless filament when heated and printed, it holds its shape and rarely warps, and it does not require a heated bed to use.

PLA is offered in a variety of colors in two sizes. It has good strength and durability but is a very stiff material, so please don’t try to bend it or it will break.

This filament is highly recommended beginners to avoid major headaches and get the hang of 3D printing.

PLA is good for hobbyist tinkering with their printer, creating prototypes, home goods, and simple toys.

Some notable subtypes:

- Carbon Fiber PLA – lightweight and very strong

- High-Speed PLA – produce quick-turn parts by maxing out your print speed

- Glow in the Dark PLA – who doesn’t like toys that glow

| Avg. Print Temp | 180 – 220 °C |

| Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Blue painter tape |

| Highlights | Easy to use |

ABS – Acrylonitrile butadiene styrene

The second most popular filament type for 3D printing, and by popular, I mean most widely used. It is a very durable plastic, slightly stronger and much more durable than PLA, and it can withstand impact.

ABS filament also can take higher temperature the PLA; however, it is slightly more difficult to print with than PLA. Unfortunately, this filament will warp when cooled too quickly so it is recommended using a heated print bed and/or an enclosed printing area.

You are able to post-process ABS in acetone, which will add an amazing glossy finish to your prints. Be sure you use this a well-ventilated area as it will put off some strong fumes will printing with it.

ABS filament is good for functional prototype parts and toys, anything that involves moving parts, phone and other electronic cases for its high impact tolerance.

| Avg. Print Temp | 210 – 265 °C |

| Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Kapton tape |

| Highlights | High impact tolerance |

Note: ABS and PLA are by far the most widely adopted and compatible filaments. To learn more about their specific contrasts: ABS vs PLA Compared.

PC – Polycarbonate

Very similar to ABS, Polycarbonate filament is a strong and impact resistant material. It is so strong that it is used in the making of bulletproof glass, although I am not saying your 3D prints will stop bullets.

It requires very high temperatures to melt and print with it, which makes it more difficult to use. If you can handle the heat, it is a great filament for its strength and durability.

Another key characteristic is its ability to withstand temperatures. Polycarbonate will hold its form up to 110°C. This filament has a little room to flex too so don’t be afraid to give it a little bend if necessary.

Polycarbonate is good for parts that need to stay strong and durable, drone accessories, mechanical and automotive parts, various screens and lighting situations due to its transparent appearance.

| Avg. Print Temp | 270 – 310 °C |

| Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Gluestick |

| Highlights | Impact resistant |

Nylon

This is the most cost-effective filament in terms of its strength, durability, versatility, and weight. Often used for mechanical and structural parts. You will typically see it used as the inlay, or base layer, for many composite 3D printers.

A downfall is there are mostly branded materials, which can sometimes be made specifically for one type of printer or another. This filament prints white, but it will absorb color through post-processing in colored dyes.

It is extremely sensitive to water so be sure you have a dry box to store it in. Pelican cases are a great option as storage. It may not be the most used filament, but it is definitely a contender for one of the best 3D Printing filament options available.

Nylon filament is good for tooling, inlays, functional and working prototypes, mechanical parts, and pretty much anything else.

| Avg. Print Temp | 240 – 275 °C |

| Diameter | 1.75, 3.0 mm |

| Bed Adhesion | PVA glue |

| Highlights | Cost-effective |

PET (PETG PETT) – Polyethylene Terephthalate

While most PET filaments will not be a true PET, but a slight modification, they still make great filaments for 3D printing.

PETG filament is one of the more common variations of PET. It’s known for the industrial strength of ABS and the ease of use of PLA. It is more flexible than PLA but much easier to print with than ABS.

It is a great middle ground filament. You need to be careful with PETG as it absorbs moisture just like nylon. Be sure you have a dry box for storage and the filament is completely dry before printing with it.

PETT is another very popular variation of PET. Transparent in color slightly stronger than PETG filament, PETT is another great choice. It is almost identical to PETG except for the two things just mentioned.

PETG/PETT is good for mechanical parts, functional prototypes, electronic cases, and clear parts.

| Avg. Print Temp | 230 – 260 °C |

| Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Blue painters tape |

| Highlights | Strength and impact tolerance |

ASA – Acrylonitrile Styrene Acrylate

Asa is very similar to ABS with one key distinction, it is UV resistant. This filament remains strong and keeps its original appearance after spending some time in the sun. ABS tends to crack and yellow during its sunbathing sessions.

ASA is a great option for creating things that will spend the majority of their life outdoors. It is still a dense, durable, and strong material just like ABS. This is a temperature sensitive filament when it comes to cooling. Be sure you use this with a heated bed and enclosed print area to prevent cracks.

ASA is good for automotive parts, and camping/outdoor gear and decorations.

| Avg. Print Temp | 230 – 260 °C |

| Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Hairspray |

| Highlights | Strength and impact tolerance |

Most Flexible Filaments for 3D Printing

These filaments are materials that can be twisted, turned, and bent without breaking and still return to its original shape. You can find a range of stiffness for the flexible materials depending on your application of your final product. If you are able to master the art of printing with flexibles though you can really have some fun with the items you print.

TPU/TPE

TPE and TPU filament are two of the most common flexible filaments you will find. These materials are very rubber like and can bend or move however you want them to. It is a difficult material to use as it can lead to a lot of clogs if you don’t have the right equipment and aren’t sure how to print with this material.

You need to print these flexible materials at much lower speeds to prevent clogging and stringing. This is one of the least common filaments and usually is only used for special projects or one-off prints.

TPU/TPE filament is good for: parts that need to be stretched, formed, or twisted – stoppers, belts, caps, cases, etc.

| Avg. Print Temp | 200 – 240 °C |

| Filament Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Blue painters tape |

| Highlights | Pliable |

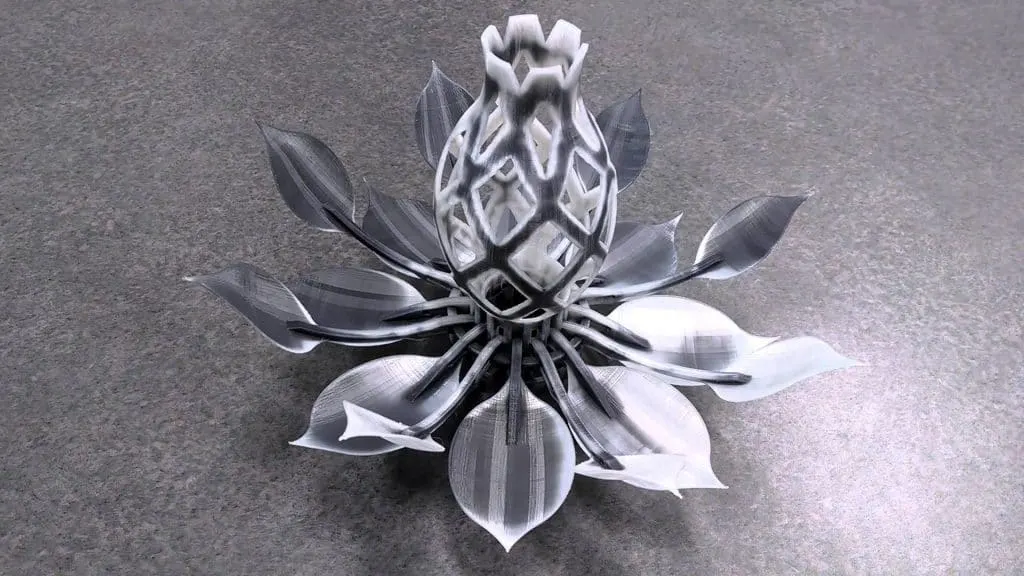

Composites Filaments and Specialty Filaments

Now that we covered your standard filaments let’s take a dive into the world of specialty filaments. These filaments are not the most common and will mostly be used for special projects. But who knows, you may just find your new favorite filament in this bunch.

There are a variety of different characteristics you will find in this category. Multiple finishes, post-processing techniques, super-hero strength, the list goes on. Now let’s dive into the different types.

Wood

The different brands of wood filaments will give you 3D object the look and feel of fiberboard, or real wood. While it may look like the real thing, don’t be mistaken, it’s actually just a PLA filled with wood fiber.

This mixing of the materials is necessary to be able to 3D print the filament. You can’t really just stick a 2×4 on top of an extruder and expect anything to happen. Either way, this composite material gives you the majority of the characteristics of real wood.

Your objects can be cut, painted, and even sanded to put your finishing touches on them. Maintaining your print temperature is a must with this filament. Get it cooking too hot and the wood fibers will begin to burn and give your printed 3D object a darker look than you may have wanted.

Wood is good for: The objects have a great finished look to them so consider this for any objects you will want to display on a desk or shelving, bowls, figurines, and small-scale 3D model objects, or creating your own sculptures.

| Avg. Print Temp | 200 – 240 °C |

| Filament Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Blue painters tape |

| Highlights | Appearance |

Metal

Don’t like the look of plastic parts and you’re not a fan of a wooden appearance either? Then how about metal. This is another blended filament. The composite is a mix of PLA or ABS with a powdered metal.

Often the metal will be brass, bronze, aluminum, steel, or copper. Typically, you will find a 50/50 mix of the plastic to metal ratio. Occasionally, you can find up to a 85/15 metal to plastic ratio.

These filaments have the look, feel, and weight of a metallic object. If you are going for the shiny look, just a little post processing polish will do the trick.

Metal filament options are rather abrasive and will wear down your nozzle rather quickly. Be sure you are ready to replace your nozzle if you are using this filament.

The metal filament is good for jewelry, tools, toys, props, pretty much anything you would create with PLA or ABS.

| Avg. Print Temp | 200 – 240 °C |

| Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Glass |

| Highlights | Metallic look and feel |

Color-changing

Remember when the cool kids use to wear those “mood rings”? Well, the same idea with this filament. It will change its physical characteristics, mainly color, based on its temperature.

While some of the colors, the filament can change to may be somewhat limited, the filament is still a lot of fun to use. The base material is again PLA or ABS mixed with the color changing particles. These filaments will be very similar to printing with standard PLA or ABS filaments.

| Avg. Print Temp | 200 – 250 °C |

| Diameter | 1.75, 3.0 mm |

| Bed Adhesion | Blue painters tape |

| Highlights | Color-changing |

I hope this guide helps you better understand the world of 3D printing filaments. There are so many that it can get very confusing very quickly. No matter what your project is, I am sure there is a filament for it.

Just be sure you understand your filament before trying to use it. You need to know the print temperatures, speeds, chemical properties, and characteristics as a start. If you do your research before, you will save yourself a lot of headaches, time, and wasted filament.

With that said, don’t be afraid to experiment and learn on your own if you have the resources. Let us know what we left off and we will be sure to get it on our list.

Sandstone

Mixing sandstone into your printing filament will make your finished products ideal for architectural, museum, or landscape display and structural needs.

Because of it’s made of chalk dust particles mixed in with PLA, it’s not food safe, and it will be more brittle than non-composite materials. This is for more look-don’t-touch types of projects.

Magnetic iron

You can 3D print your own magnets with this kind of filament. It’s another type that needs special monitoring of its printing temperature and flow, but it comes out strong and ready to stick to conducive surfaces.

Conductive PLA

This kind of filament combines PLA with a conductive carbon particle that lets you print low-voltage electrical circuits. If you’ve got a dual extruder, you can 3D print a whole circuit board in one go. But just like anything that conducts electricity, be careful! Apart from breaking if bent too much, this kind of filament is expensive to replace and can be dangerous if you’re careless.

Carbon Fiber

Think of this as an upgraded PLA. It prints the same but adds extra layers of rigidity, layer adhesion, and easy support removal, making it great for protective casings and other high durability applications. Just be warned that it can wear out your printer’s nozzle if the nozzle isn’t made out of or protected by a harder material.

Resin Filaments

These are for all your stereolithography and digital light processing needs. Keep in mind that each of these types cater to a niche of a niche in 3D printing, so it may be difficult to find reviews of specific brands. If you’re uncertain, search for photos of finished projects using the materials you’re thinking about buying to see how the details will come out.

General purpose

These resins are the basic photopolymers first designed for 3D printing. In their first iterations, they were limited to a transparent yellowish cast, but since SLA and DLA printing has become cheaper and more accessible, their colors and opaqueness have expanded.

Tough

As more companies begin using 3D printing for practical purposes rather than strictly aesthetic, they need less fragile resins that can stand mechanical wear and tear.

Resins that combine the flexibility and strength of ABS other filament-based printing materials with the unique layering process of SLA or DLA printing are popular with printers who need high wear resistance.

Castable

Castability has always been high priority for SLA and DLA printing. Industries such as dental and jewelry manufacturers fabricate parts that are designed to be cast in metal, and with this type of resin, it’s easy for their prototypes to translate into whatever shapes are needed. A good castable resin has a high burnout so the polymer material will burn completely off the finished product.

Flexible Filament

Like their traditional 3D printing relatives, resin 3D printing resins are for goods that need a little give, like water bottles or door handles. But be careful about bending these too far – they’re prone to tearing if pushed beyond their limits. If you are looking for a 3D Printing to use with flexible filament options, read our guide here.

High-temp

Formlabs has created a unique resin designed to withstand heat up to 289 degrees Centigrade. It’s deflective enough for industrial use as well as desktop SLA, great for printing injection molding tools, thermoforming tools, and heat testing channels.

Biocompatible

Dentistry is the main industry that currently benefits from a resin that’s safe for human contact, but the whole medical trade can take advantage of this special blend. It’s great for the fabrication of surgical and pilot drill guides.

Ceramic

Once printed into a 3D printed object, this resin can be fired in a kiln, glazed, and treated like a general ceramic. The polymer binds to ceramic and add its density to the final product.

Daylight

If you can’t afford a laser or specialty light source, this resin may be just what you need to get into SLA printing. These photopolymers react to ordinary sunlight filtered through an LED screen, which has the potential to drive down SLA costs for a mainstream audience.

Open-source

Resins are improving all the time, and many folks are putting their recipes up for grabs. Just be mindful of what you need from your SLA or DLA experience, and you can even make your own based on what you find.

FAQs

Are is 3d printing filaments expensive?

Certain 3D printing filaments that offer a higher level of quality and makeup are generally more expensive and you can expect to pay $25 per kg or more..

What 3D filament is food safe?

3D filaments that are considered food safe include PLA, PP, co-polyester, PET-G, HIPS, nylon-6 and specific brands of ABS, ASA, and PEI.

Is PLA Filament toxic?

PLA can release toxic fumes known as Volatile Organic Carbon (VOCs) which are usually not toxic to breathe, but, sometimes they can be.

Is it safe to 3D print indoors?

Not entirely. Particles emitted during the 3D printing process can have a negative effect in your indoor environment and reduce the quality of the air you breathe and can potentially harm the respiratory health. This is more true for certain filaments than others.

Is it safe to 3D print overnight?

No. Never leave the 3D printer during the process unattended. There are many cases of fires breaking out and spreading.

Is PLA safe for creating food cutters?

Natural PLA is considered food safe, but some manufacturers add other additives for enhancing the PLA’s strength, color and other features which makes the filament unsafe so make sure you know what you’re using if you want to create food cutters.

Finale Word on 3D Printing Filaments

Finding the best materials and filaments for your 3D printing projects doesn’t have to be overwhelming. When you have a good idea of why you’re making something, you’ll be able to make the best choice with the help of our handy list. Happy printing!

Further read: