- Creality Ender vs Anet A8 [2022]: Which is Better? - April 14, 2022

- TEVO Tornado Review [2022] All You Need To Know - April 6, 2022

- Anet A6 Review [2022 UPDATED Version] - April 5, 2022

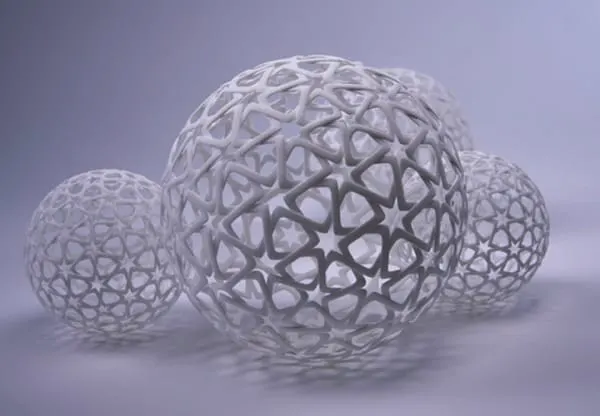

One of the biggest factors in the adoption rate of new technology is how easily people can adapt to it.

Users are much more likely to be drawn to something that is easy to understand and straightforward as the quicker they can master it the more they can enjoy it.

Unfortunately, 3D printing is not the easiest to understand or the most straightforward concept, but that’s okay — we’ll make it easy for you here, which is why we are comparing these two filaments: ABS vs PETG 3D, so you can decide which is best to 3D print with.

Table of Contents

The Main Differences Between ABS vs PETG 3D

The main differences between ABS vs PETG 3D are:

- ABS is not a sustainable, environmentally friendly filament, whereas PETG is recyclable

- ABS is extremely an extremely durable, lightweight filament, whereas PETG absorbs moisture, so you have to store properly

- ABS requires a heated bed, whereas PETG does not required a heated bed

- ABS is a thermoplastic polymer typically used in lego building blocks, whereas PETG is a glycol modification material typically used in plastic water bottles

A Little About 3D Printing

Not only do you have hundreds of choices of 3D printers that all seem very similar to the naked eye, but you also need to understand the filament you are using.

The filament for a 3D printer as is important as the jelly in a peanut butter and jelly sandwich. You can’t have the printer without the filament (3D printing material). These days there are a ton of different filament types for printing. And who really knows the differences between them all. Aren’t they all just spools of plastic?

While some are spools of plastics, they each have very different characteristics. Some are hard, some are soft, some are flexible, some are strong. You get the point. Filament alone can take days upon days of reading and research to just begin to understand some of the basics. Luckily for you, we can do much of the research for you.

Just as anything else, there are some types that are more popular than others. Without a doubt, PLA is the uncontested champion of the 3D printing world. It’s great for all skill levels. It is super easy to use and has a low melting point. It is just an all-around pretty awesome filament. But we aren’t here to talk PLA all day. Let’s discuss some other filaments.

What are ABS and PETG?

Acrylonitrile Butadiene Styrene (ABS), is a thermoplastic polymer, and it is the second most popular 3D printing filament right behind PLA (polylactic acid ). ABS is popular as it is extremely durable (ideal for mechanical parts with mechanical properties), very lightweight, and relatively cheap to produce and purchase.

You can associate ABS as the material used for LEGO bricks, as well as other consumer goods. It is a very popular material to be used for injection molding.

There are some drawbacks to this filament. It requires high temperatures to reach the ideal melting point (225C). This means you will need to have an extruder that can reach these temperatures (heat resistance) and a heated chamber print bed to avoid warping.

A good ventilation system (e.g. a cooling fan) will help the melted material set and strengthen as it requires such high printing temperatures. As well, ABS puts off a strong, unpleasant odor that can become toxic to humans and pets if too much is inhaled.

Another downfall of ABS is the negative environmental impact. ABS is not a sustainable filament. It is not made of recycled material nor biodegradable material. Any bad prints and unused/unwanted filament will most likely live on for ages in the town dump. Be sure to get your settings dialed in to limit the amount of waste you produce when printing with ABS.

The other filament is an up-and-coming filament that I quickly becoming a favorite of many 3D printing enthusiasts. Polyethylene terephthalate (PET) is the base material with the G representing a glycol modification. This modification adds a lot of durability to PET. PET is most commonly known as the material used for plastic water bottles.

PETG material maintains a reputation as the best of both worlds for 3D printing’s most popular filaments. It has the tensile strength, temperature resistance, and durability of ABS. Those are combined with the ease of printing PLA and you can understand why PETG is quickly becoming so popular.

Some of the more noteworthy aspects of PETG are that the 3D printer filament is recyclable. It is not the most sustainable material, but it is better than sending PETG print misfires straight to the dump.

Also, PETG is food safe if you want to make any storage containers for edible treats. And this filament does not require a heated bed in order to print without warping (can work on heated or not heated surface plates).

While PETG is quite impressive as a filament, it still has its pitfalls. For example, PETG is a hygroscopic material, which means it easily can absorb moisture. If PETG is not stored in a dry place to keep humidity and moisture from it, the dampened filament will not print how you want it to.

Pelican cases make a great storage box/dry box for PETG. Also, this filament does not do well in UV light. This isn’t the end of the world unless you wanted to print something that would be used outdoors often. The little makes the material become brittle and breaks apart easily.

What makes it popular?

ABS’s strength and durability make it a great choice for a wide range of products and industries. It withstands heat and stress without cracking or weakening, and it is one of the strongest plastic filaments you can buy.

The finished product will hide scratches and is highly resistant to chemicals (chemical resistance) and lights. This makes it a great material for finishing polishes, paints, glues, and other post-manufacturing processes.

ABS will print very smoothly as long as you have your printer settings dialed in. As mentioned before, it has a very high melting point so you will need to ensure you can reach and sustain temperatures throughout the duration of the print. It is recommended you use an enclosed printer as this will make it easier to maintain the temperatures.

PETG, on the other hand, is also known for being a tough and durable filament. A plus-side of this one is it is odorless when melted. While tough and durable, it is also maintained soft and flexible characteristics. This makes it great for prints such as cases, bumpers, and protective pieces. However, this is not the ideal filament for structural or stiff pieces.

Best Practices

It is no secret that filaments can be very tricky to print with. If your printer is dialed in exactly to where you need it, you can end up with a sloppy, stringy, mess of plastic. Nobody wants that. This is why it is very important to pay attention to the specific traits for whichever material you choose.

PETG happens to be one of the more particular filaments and much less forgiving than some other types. Just remember to be patient and check the box on all the details before you rush into a print.

Depending on your extruder and extrusion settings, PETG needs to be printed between 220-245C. While not necessary, a bed temperature around 75C is ideal. You don’t need to get fancy with your bed adhesion. Blue painter’s tape works just as well here as it will for most other filaments.

Unlike some filaments, PETG doesn’t smear onto each layer from the extruder. Instead, it lays down better on top of each layer. Because of this, you need to leave slightly more room, about 3mm, between the print bed and the nozzle. It is a little tricky to get your printer and nozzle dialed perfectly, but once you get it there, it is nothing but smooth sailing with this filament.

ABS, can also be painful to work with if you don’t take your time (specifically the nozzle modifications). This filament should not be used with an open-framed printer as a lower printing temperature can cause the filament to cool quickly.

The rapid cooling will lead to warping and weakening the final print. If you only have an open-framed printer, you can try using plastic wrap to simulate an enclosed printer. Creating a perimeter around your printer will allow you to maintain some of the heat and block unwanted drafts and cool air.

ABS also needs to be used with a high-temperature extruder and a heated bed for best results. After the first few layers have been laid down, you can lower the temperature of the heated print bed. But you want it to be hot at the start to prevent rapid cooling.

ABS vs PETG Price Difference

For ABS 3D Printing Filament you are looking at about $20.00 for a decent spool of filament. The PETG Filament is slightly higher at $27.00 per spool.

Both materials are right on par with most other generic types of filament, which float around $20 to $30. Of course, there are specialty spools that can run you anywhere from $50 all the way up to $100.

Also, be aware of where you are purchasing your filament. Some websites will appear to offer legit filament only to send you the bottom of the barrel filament, which does nothing but cause headaches when trying to print. Be sure you are purchasing from a legit supplier. It is always better to spend a little extra to be assured you are receiving a high-quality filament.

Where to Buy PETG Filament?

Just like your classic printers, brands may guage you on their own “custom” filament. They tend to push THEIR brand, regardless of the many suitable (if not even better) alternatives.

My top recommended filament source is definitely Matterhackers PRO series PETG filament here. It works with all of the top 3D printers, with higher reliability and often a lower price.

Where to Buy ABS Filament?

Similarly, the Matterhackers ABS filament here is second to none.

Final Takes: PETG or ABS?

We know PLA is the most popular, but a close second is ABS. Just because something is popular doesn’t necessarily mean it is the best.

Depending on who you talk to, a lot of people will argue ABS is the best, and some will even state their case for PETG. Both ABS and PETG are making a name for themselves among 3D printing enthusiasts.

While ABS and PETG are quite similar, they each are different and have their unique qualities. Test your settings, and give each a try to determine which is the best for you.

While some will choose one side or the other, many people will find ways to incorporate both filaments into their designs.

Recommended Reads

- ABS vs PLA Filament Compared

- Best Carbon Fiber 3D Printers

- Best Wax 3D Printers

- Best Nylon 3D Printers

- Monoprice Maker Select Plus 3D Printer Review: Will You Love It?

- The Full Bibo 2 Touch x Laser 3D Printer Review: A Good Budget Option?

- The Ultimate Simplify 3D Review: What Will You Think?

- The Best 3D Printing Pens for 2020