- Flashforge Creator 3 Review [2022]: Our Honest Opinion - April 5, 2022

- Anycubic Photon Review [2022]: Will This Work for You? - April 5, 2022

- X-Carve Review [2020]: Is This CNC Machine Right For You? - April 4, 2022

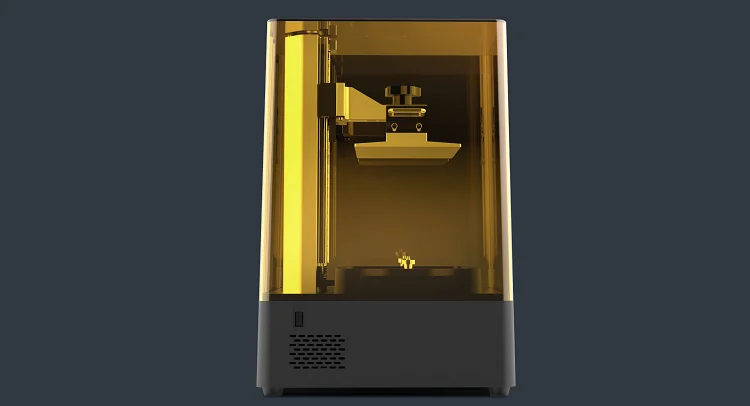

Are you looking for a high-precision, high-definition resin printer for your desk with minimal fuss and maximum compatibility? This article is a comprehensive Phrozen Sonic Mighty Review and guide, likely the perfect printer for you.

This 3D printer features a build volume of 260x260x250mm, a resin tank capable of holding up to 1.2L, and can be connected via USB or wireless for maximum convenience.

The mighty is taller than it is long, with the tank on the right side taking up much of the available space in front-to-back dimension. The printer weighs about 8kg without the tank, which is not too heavy for a resin 3D printer.

The Sonic Mighty – Bottom Line Up Front

This compact printer is great for beginners because it’s easy to use and not overloaded with complicated features. However, it’s not great for advanced users who may want more versatility.

Design

The Mighty has a very simple design with two printed pieces locking together to create the printer’s body and having its functional parts attached directly to said body or housed in smaller boxes on top of it. The build plate is heated with what I think are 5x 100mm metal rods screwed to a replaceable metallic build plate.

The build plate does not have any insulation under it, so the only way to control its temperature is by monitoring/controlling the resin tank’s temperature very closely, which is a good thing for people who don’t want to deal with complicated setup procedures.

The two big silver knobs on the front and back of the printer can be turned to increase or decrease its height. This is useful for leveling the build plate and moving it around, although because resin printers are usually plugged in directly to a power socket, they should not be moved around too much.

The mighty has an LCD screen with four buttons underneath all functionalities available in the menu. The blue backlight of this LCD screen is very bright and can be distracting when using it at night or in a dark room.

Resin Tank, Lights, and Tubes

The resin tank on this printer can hold up to 1.2L of liquid resin and is 19cm high (7.48 inches) and 10cm wide (3.94 inches) and is made of see-through plastic material, all very standard characteristics for resin 3D printers.

The tank sits on the right side of the printer. It has a special hole that allows you to pour resin into it from both sides, making refills very easy even if left-handed. This hole can also be used to decant resin into the tank when it is almost empty, but make sure you clean this area well and let it dry before using it again.

On top of the resin tank, there are LED lights. These are very bright LEDs that could potentially cause problems if aimed at your eyes for a prolonged period. The tank has a little window on top that allows you to see the resin level and acts as a guide for the tube that sends fresh air into the tank to prevent bubbles from forming and ruining your print.

The Mighty has an automatic cleaning system that sucks up excess resin inside the printer and pumps it back into the resin tank. This system constantly runs unless you manually turn it off by holding the power button down for 5 seconds, which is a good security measure because resin tanks are expensive pieces of equipment that would be hard to replace if broken.

Connections

The mighty has two different ways to receive commands from your PC/Mac: USB cable or Wifi connection. This is a very nice feature and makes this printer ideal for people who work in large spaces and do not want to deal with wires or people who can’t be bothered to plug in the USB cable every time they need to print something.

Another thing I like about the mighty is the metal door on its back, which allows you to easily access the print bed and get prints out once they are done, without disassembling parts of the printer.

Bed Leveling and Maintenance

Like most resin 3D printers in this price range, the mighty requires manual bed level calibration after every major part replacement or upgrade, and this can be a real pain to do.

Luckily once you get the hang of it, this process goes pretty fast and is usually only required every few weeks, depending on how much resin the printer uses.

The mighty has a very flexible glass bed with an automatic leveling system that I think works well as long as you take care of your prints and don’t leave them unattended for too long (like you would on any other resin 3D printer).

The glass bed also has an anti-stick coating, which effectively keeps prints stuck in place while printing, but wears out pretty quickly and will need to be replaced if you want your prints to stick better. The shiny side of the bed should always face up when printing, or the printer will not be able to find it.

To access this part of the machine, you must open the back metal door by pressing down on a small latch that holds it in place. This is where you’ll need to pour fresh resin into the tank, replace the glass bed and take it out if necessary.

Once you get to this part of the machine, always make sure that you wear gloves because gummy resin will be all over your hands (and probably in your hair) until you wash it off thoroughly. You may want to do this somewhere accessible to clean, like in your shower or front of a bathtub, because this stuff is very sticky and messy.

Resin Tank Cleaning

Cleaning the resin tank every 50-100 prints is required to prevent print-quality degradation due to excess bubbles or hardened resin that blocks fresh supply from reaching the nozzle. To do this, you’ll need to disassemble the resin tank and clean it thoroughly with high purity IPA or Acetone, then let it dry.

The printer will not be able to print if this area is dirty. Check these two areas of the tank before every cleaning session to make sure that they are completely dry because having even a few drops of water there could damage your prints.

Printing and Settings

I like to set the thickness of the resin, which is supposed to be around 1mm, in manual mode at 100% and then feed it through multiple times until I get a nice solid print with no bubbles. This helps even out and speeds up the printing process quite a bit.

If you’re using Simplify3D software, you can set the number of passes that happen under the printing settings before it starts printing. With Slic3r, you will need to use other methods to achieve this functionality.

The layer height should always be 0.1mm for best results with this machine because if your models are too big or have fragile parts, they will be tough to keep in place and may even fall over and detach from the print bed.

They usually recommend using a raft with all resin 3D printers, but I prefer not to unless I’m dealing with a complex object that needs more support than usual. Rafts can easily create additional work for you because they require much more cleaning than simple prints, and they add to the prints’ overall weight, which can cause issues with your glass or print bed.

Although I’ve been able to get good results without a raft, priming the resin tank beforehand helps a lot because it will not have all of those bubbles in it from being stored for so long. If you don’t prime the tank, your prints will usually have lots of very tiny bubbles in them.

When priming the tank with fresh resin, I recommend printing something tiny that will not take too long to print and waiting 15-20 minutes before starting it to make sure that the resin is thoroughly mixed. When you remove this part from the machine, the resin will be gummy and not print correctly.

If you choose to use a raft, I recommend priming the tank beforehand because it will help prevent tiny bubbles from getting trapped beneath it. Other than that, make sure that your model is big enough not to detach off of the raft or glass bed while printing.

Slice Settings

I get the best results with 0.1mm layer height at 6-10% infill. Although every model is different, you should always check your slicer to ensure that it’s strong enough before wasting a lot of time on something that may not come outright. Printing at 100mm/s in minimal quality with 10% infill usually gives me a decent result.

Once you have your print-ready, there are just a few more things to worry about before it can be showered in high purity IPA or Acetone and turned into a beautiful resin piece of art!

If you want to add color to your prints, I recommend using color-infused filaments such as Proto-pasta powders or Palette+. It will help with resin to PLA adhesion and give your prints a whole new level of detail.

Bubbles

If you’re getting bubbles in your prints, it’s time to take a look at the entire process because there could be several reasons for this issue.

First, check that there are no bubbles in your resin tank and that it’s completely dry on the surface where the print head will touch it. If you have a bubble or two at this point, try to pop them with a 3mm drill bit.

If this doesn’t solve your problem, then look at the resin tank and see if you can spot some bubbles stuck to it. Try to get as much of that plastic-like bubble gunk off the surface as you can and then wash it with high purity IPA or Acetone, making sure not to touch the bottom where your prints will go on top of later on.

If your resin tank is still not producing perfect prints after all of this, then try using a command strip or wire to pop the bubbles that are trapped in your print. These can be very difficult to spot depending on how big they are, but you will get better at noticing them with time.

PLA Adhesion

If one or both of your priming layers produce bubbles, then the issue has something to do with your print bed. It’s either not level, is too high above where you are printing on it, or the blue painter’s tape doesn’t cover that I use all of the time.

If you can’t seem to get rid of them even after priming your resin tank, I recommend using a thin layer of color-infused filament to create the first few layers. This way, your print surface is not getting hit with resin right away, and you can make sure that it’s completely flat before starting your build.

Another thing to try here is putting down some white glue or silicone on your print bed just before printing since these will soak in a lot of the extra liquid, preventing the bubbles from going into your print.

Extra Care

There are some small things that you can do which may even improve the quality of your prints when they come out of the resin tank later on.

To prevent dust from settling onto your print after it is done, use a thin elastic band to hold it onto the print platform. This will prevent unnecessary movement and protect it from accidents that may happen at home or in the office, preventing unsightly damage that could be avoided.

I know this may sound like a lot of extra work, but when you get used to these steps, they’ll become second nature, and you can enjoy the newest technology that is now available for us to 3D print with.

Even after all of this effort, you can still come back and find air bubbles in your resin prints, so I suggest keeping at least one backup part on hand just in case!

Using high purity IPA or Acetone will also help thin out any air bubbles inside your prints.

When you’re all done, take a look at your shiny new print and give it the treatment that it deserves!

Sonic Mighty Alternatives

If you’re considering purchasing a 3D printer, there are plenty of options on the market outside of the Phrozen Sonic Mighty. Here are some other models you may want to check out first.

B9Creator

The B9Creator is a great option and will give you some advanced features that the Phrozen Sonic Mighty lacks, like a resin tank holder, built-in flash storage and camera, and a powerful software suite.

As of right now, it does not have an integrated resin tank, but there is one available for purchase separately that will work with this model.

3D Systems Cube Pro Duo

The 3D Systems Cube Pro Duo is another solid choice. This machine is very bulky, so you’ll have to make sure that there’s enough room on your desktop for it. There are some issues with the software, and the print quality is not as great as other options on our list, but for something sturdy that can be upgraded to match your needs over time, this is a great option.

Cubify CubeX Duo 3D Printer

The Cubify CubeX Duo 3D Printer may be a bit more pricey, but the print quality is much higher as a result. This printer uses digital light processing to produce prints with remarkable detail and sharpness.

This model does not have an integrated resin tank, but the software and hardware are compatible with other options.

Formlabs Form 1

The Formlabs Form 1 is the only stereolithography 3D printer on our list. This model uses laser light to cure light-sensitive resin into a solid form, producing prints that are entirely smooth and have an incredible resolution.

There is some assembly required for this model. It also involves a lot of tinkering with the settings before you can get the perfect print.

FAQs about the Sonic Mighty

If you’re on the hunt for a 3D printer, you may have some lingering questions. These frequently asked questions may help you make a better decision.

Question: How Does a 3D Printer Work?

Answer: A 3D printer comprises three major parts: A printing platform, a resin tank, and a laser.

The printing platform is where your model will be printed. This part moves up and down to position the resin tank at the correct height to create a solid layer of resin on top of the platform.

The resin tank is filled with light-sensitive liquid resin. The laser cures the resin into a solid form by exposing it to ultraviolet light.

After each layer is cured, the printing platform moves upwards, and another layer is placed on top. This part continues to repeat until your print is complete.

Question: What Types of Things Can I Create with a 3D Printer?

Answer: The possibilities are pretty much endless! If you have a 3D model, you can print it out so long as it’s saved in a file type that your printer can use.

You can also print out custom parts for household items, toys, games, and more! If you have a specific need, you may even be able to print out the object in full.

Question: How Much Does a 3D Printer Cost?

Answer: The average cost of a 3D printer is around $2,000. However, there are several available that are under $1,000.

The Phrozen Sonic Mighty is one of the cheapest options on our list. At only $1,099, this printer provides a decent value so long as you don’t expect it to do advanced functions.

Question: What are the Dimensions of a 3D Printer?

Answer: The Phrozen Sonic Mighty is 18″ x 20″ x 24″.

This compact desktop printer should fit well on most desks. As long as you have a bit of open space around it, you shouldn’t have any issues with the design of this printer.

Question: What’s the Difference Between a 3D Printer and a CNC Machine?

Answer: A CNC machine, or computer numerical control machine, is a cutting tool that operates on the same principles as your average laser printer.

A CNC machine works by moving a cutting tool along two axes at different speeds. The positioning of the cutter is controlled by a computer connected to the device.

A 3D printer is a lot simpler than that. The tool outlines the model’s shape and then cures it with resin, layer by layer, until it’s complete.

Question: What are the Different Types of 3D Printers?

Answer: As of right now, there are two main types of 3D printers.

The first type is FDM or fused deposition modeling. This process uses a plastic filament that is melted and formed into layers. The melted plastic is pushed through a metal nozzle heated to the appropriate temperature to create each layer.

The second type of 3D printer is SLA or stereolithography. This type cures resin with laser light to create layers.

Phrozen Sonic Mighty – Final Thoughts

The 3D Phrozen Sonic Mighty makes an excellent entry-level printer for beginners with a compact design and easy-to-use software.

This model doesn’t have a heated print bed, so advanced users may want to look elsewhere. Additionally, it isn’t built for large prints. If you need something that can handle more advanced models, you need to look for a higher-end 3D printer.

However, this model might be a good fit if you’re looking for a printer that’s capable of light prints and offers easy operation at an affordable price.