- How to Remove 3D Print From Bed - May 31, 2022

- Autocad vs Inventor: Which Software is The Best? - April 5, 2022

- Autocad vs Revit [2022]: Which Is The Right Choice? - March 31, 2022

When you take the plunge into 3D printing, it’s easy to get caught up in the machinery. It’s the most obvious aspect of the whole process, and there are almost as many choices as there are possible projects – but, choosing your hardware is not the ultimate destination of your 3D printing journey.

That distinction goes to finding the perfect software for your needs. Your hardware is only as useful as your software lets it be, so make sure, first of all, to be honest about your own starting skill levels, time and patience to learn something new.

We’ve given you a comprehensive guide on how to navigate the hundreds of different options out there, so now we’re going to focus on the merits of the two most popular: AutoCAD and Solidworks.

These are both programs with legacies of excellence in drafting and 3D modeling with plenty of support, both official and amateur, so at first, it may seem like you can pick whichever one is on sale, or whichever one your favorite YouTube 3D printer uses, and it won’t matter in the end.

However, there are plenty of distinctions between AutoCAD software and Solidworks for 3D modelling that you need to consider before choosing. It’s like the options of an Apple or Windows computer – they’ll both get you to the same place, but the ways they get you there are different, and you should know the individual steps of each so you can use your smoothest path.

One thing to keep in mind – both of these programs are designed for users who already have some computer-aided drafting and computer-aided design experience.

That isn’t to say you need an engineering degree to get what you want from them, but just keep in mind that a basic familiarity with drafting concepts (or the willingness to spend extra time Googling them) will help you orient yourself within these systems no matter which one you pick.

Bottom Line Up Front Summary: Solidworks is fine for JUST 3D drafting, however I would recommend upgrading to AutoCAD here if you planning to operate a serious business with both 2D and 3D crossover needs, or may need reliable support. Autodesk IS the market leader for CAD and as such updates their products more frequently (free upgrades) and generally pioneers new features. AutoCAD also “plays better” with the other Autodesk software suites.

The Gold Standard for industrial CAD, AutoCAD LT can flexibly adapt to 2D or 3D projects, while using local network drives if connection speeds are limited. Most additive manufacturing speaks AutoCAD.

Table of Contents

Main Difference Between Solidworks vs AutoCAD

These are the main differences between Solidworks vs AutoCAD:

- AutoCAD is better for 2D drawings and non-parametric design, wh2ereas Solidworks is best for 3D Design and parametric design

- AutoCAD is generally less expensive compared to Solidworks

- AutoCAD is more flexible for both 2D and 3D CAD, whereas Solidworks is better for dedicated 3D rendering

Let’s get into the tool details:

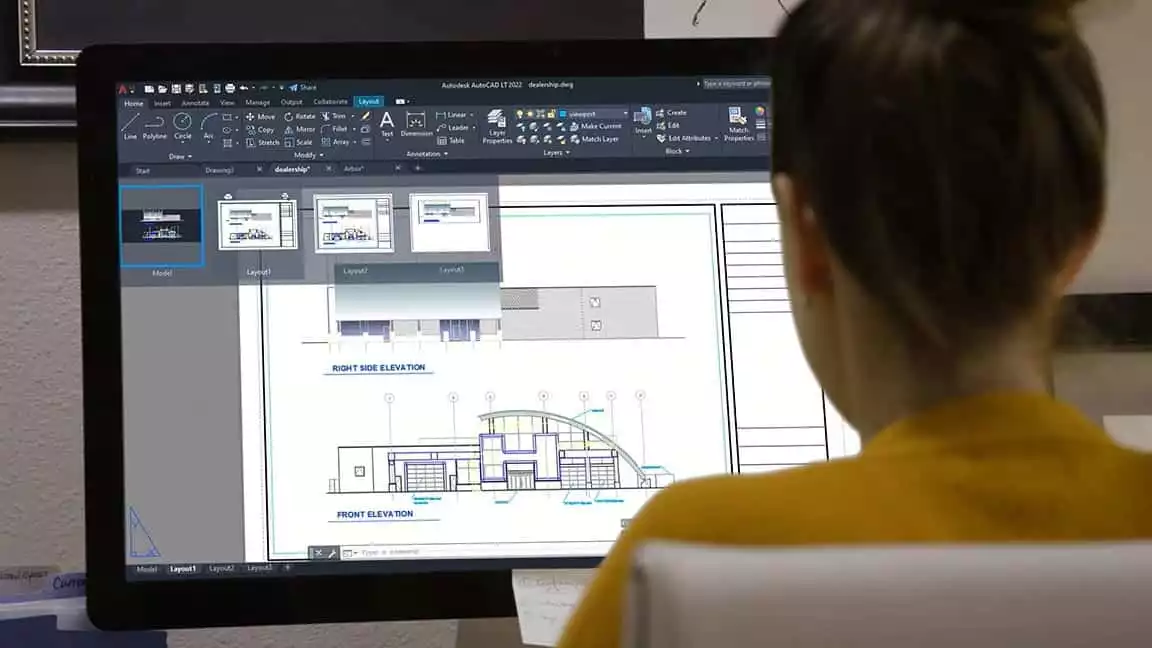

AutoCAD Tool

AutoCAD Software Functionality Overview

AutoCAD is a computer-aided drafting software developed by AutoDesk in 1982. It came from a 1970s software called Interact CAD (computer aided design) and was the first drafting program developed for personal computers rather than the minicomputers that were common at the time.

It was an instant hit and revolutionized the drafting game with innovations such as the ability to work on multiple drawings at a time and object transparency. Since its introduction, it’s become the most-used software in the design world.

AutoCAD 3D started as a way to model 2D geometry and evolved to include various 3D modeling options like solids, surfaces, and meshes. Many drafters still use it primarily for 2D drawings and 2D drafting (2D CAD), but its capabilities make it great for modeling your 3D printing projects.

You can turn your object in 3D space to look at it from any viewpoint, which makes it very useful for a full-object visualization functionality. AutoCAD also lets you attach notations to your drawings, attach and import data from PDFs, and extract object data to tables, so you can present your data and real-time analytics as separate from the shapes.

Most recent from AutoCAD

The latest version, AutoCAD 2020, was released in March of last year and supports 4k monitors, or ultra-high definition monitors that have four times the amount of pixels than traditional high-definition monitors. Translation – it looks great on computers that have the power you need for heavy-duty 3D modeling design work and CAD software applications.

The new edition also introduces an improved version of its DWG file format, a standardized binary file format used for drafting files across a host of different software, so if you’ve been using another program and are worried about losing your work, don’t be – it’ll translate perfectly over to AutoCAD. There are also plenty of ways to view DWG files without AutoCAD, and the software also supports Drawing Exchange File Formats, or DXF, which is the non-proprietary version of drafting files.

AutoCAD has grown into a group of programs customized by industry with different user interface tweaks. The AutoCAD Architecture, for example, has pre-loaded details common to building product design like doors and windows; AutoCAD Electrical gives access to a library of commonly used electrical engineering symbols.

All AutoCAD variations have applications for 3D modeling, but if you’re specifically using it for 3D printing, you probably want to use AutoCAD Mechanical, which lets you create and modify mechanical designs, or AutoCAD MEP, which is the variation that lets you solid 3D model mechanical, electrical, and plumbing designs for construction in the CAD program.

The Gold Standard for industrial CAD, AutoCAD LT can flexibly adapt to 2D or 3D projects, while using local network drives if connection speeds are limited. Most additive manufacturing speaks AutoCAD.

AutoCAD Pricing and Accessibility

A full license for AutoCAD will run you $195 per month, or $1,575 per year. The longer you subscribe, the less per month it will be, but your starting costs will go up exponentially, so unless you’re positive you’re going to use it on the regular for four years, don’t shell out the $4,252.50 that commitment will cost you.

If you’re a student or educator, you may be eligible for a free license. That doesn’t include access to all AutoCAD variations, but if you already know which one you’ll need to use, it’s definitely worth it, especially if you’re looking to start a multi-station 3D printing class.

Plus you’ll get access to AutoCAD’s cloud storage services, so you can share projects across whatever geographic differences you might have. Just remember it won’t be quite as robust per person as a full version, and you’re bound to using it only for educational purposes that aren’t for profit.

Your subscription gives you access to all the variants of AutoCAD we talked about above, so you can experiment across the different variations and figure out which one works best for your projects. This also gives you access to AutoCAD’s web and mobile apps so you can access your designs wherever you end up working.

AutoCAD is compatible with both Windows and Mac computers, and since your designs become standardized file types within the software, you’ll be able to share across all the operating systems you and/or your team prefer.

Pros for AutoCAD 3D Printing

- Full-grade professional software with massive amounts of options and features

- Pioneering innovator in computer-aided drafting that’s been the industry standard since its beginning

- Specific 3D printing command (3DPRINT) since 2015

- Wide translation across file storing and sharing across other software

- No subscription fee if you qualify for the education license

- Mobile app and cloud storage and sharing for a wide variety of accessibility

Cons for AutoCAD 3D Printing

- Originally developed for 2D design, which some say is still its strong point

- Annual subscription fee of more than $1,000 if you want to use it for profit-making ventures

- Requires a steep learning curve; best for those who are already familiar with drafting principles and want to add a 3D printing component or 3D part

SolidWorks Tool

Functionality Overview

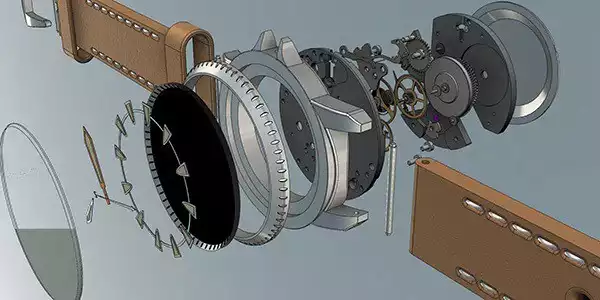

SolidWorks is a computer aided drafting software that was developed in 1995 by Jon Hischtick, founder of the SolidWorks Corporation. Dassault Systems acquired SolidWorks in 1997, and merged with its previous CAD system experience and user base. Its most recent iteration, SolidWorks 2018, was released in October 2017.

The name is a giveaway: it’s a software that models solid objects, and it does that based on engineering terms like bosses and holes rather than through geometric shapes like AutoCAD does. It also starting including simulation tools almost twenty years ago, so that users from 2001 forward have been able to test their designs in real-world situations before they actually commit to building anything.

CAD tools to simulate computational fluid dynamics, the ability to simulate fluid flow, heat transfer, and fluid forces, and life cycle assessment features let SolidWorks users see how their designs will preform under environmental pressures that they may find themselves under when they’re used for their intended purposes.

As a Solidworks user your subscription also includes a rendering process that lets its users see their objects in photorealistic finishes, project data management resources so you can make sure your drafts are as organized as you want them to be, and a SolidWorks electrical package so you can use it to add accurate schemas and circuit data while reducing the need for physical prototyping.

All of these features make it a favorite of engineers who depend on 3D modeling for their work. It’s used across a variety of industries like auto and aerospace engineering, construction, oil and gas, alternative energy, and robotics. Amtrak, BAE systems, and Daka are all both major users.

SolidWorks was developed in the opposite direction of AutoCAD; first created as a 3D modeling software (CAD software), it’s brought in 2D drawing components as well; your SolidWorks model will start as a 2D drawing as your first step. But its initial focus on 3D makes it a favorite of many 3D printers.

AutoCAD vs Solidworks: Price and Accessibility

One permanent license of SolidWorks Standard costs $3995, and you’ll pay an annual maintenance fee of $1,295. If you want to get the Professional version, it’s $7995 with a $1450 maintenance fee.

If you want to go all out, the Premium Package (CAD package) is a one-time fee of $7995 with an annual maintenance fee of $1995. The company does offer a student version for $150, but that is limited to one year’s use and puts an unremovable watermark on any work you create so you aren’t able to use it for commercial ventures.

Its 3DEXPERIENCE platform lets you share your designs and connects you with others as you want and need to for projects. It offers a marketplace where you can shop for designs from those who submitted them, and it all integrates into its PLM features for optimal project management.

One thing that may trip you up is SolidWorks’ incompatibility with Mac operating systems. You have to use it on Windows, so if you don’t have that hardware, you’ll need to find another program, and make sure all the people you want to collaborate know that as well before you choose for your whole team. However, it uses the standard drafting file extension of DWG (CAD files), so your designs will be readable across other drafting programs with no issues.

Pros for 3D Printing

- Parametric feature-based modeling makes designing (and your design process) in 3D intuitive as you don’t have to be a geometry genius to get the features you want

- You only have to pay for a licensing fee once

- Discount for student edition

- Range of simulation options let you test your design before you print it

- Built on the premise of 3D modeling

- Includes sheet metal design tools

- 3DEXPERIENCE cloud storage and sharing capabilities

- Used across a wide variety of engineering industries so is a recognized standard

- Integrated CAM

- Standardized file formats makes it compatible with other CAD programs

- Latest version allows for freehand sketching on mobile devices

- Latest version integrates CAM and topology study tools

Cons for 3D Printing

- Only compatible with Windows operating systems

- Maintenance fee required per year, which is about the same price as one AutoCAD annual subscription, on top of one-time license fee

- Reduced 2D capabilities

Final Verdict: Solidworks or AutoCAD?

The Gold Standard for industrial CAD, AutoCAD LT can flexibly adapt to 2D or 3D projects, while using local network drives if connection speeds are limited. Most additive manufacturing speaks AutoCAD.

So there you have it – the ins and outs of the two most popular 3D modeling systems on the market. And don’t forget how much support these two programs have. Because their extensive history stretches back beyond 3D printing to the beginning of computer-aided drafting as a concept, there are massive treasure troves of tutorials for both.

Whether you’re a read the 500-page manual before you touch it kind of person, or more of a YouTube it as you go dilettante, the internet has you covered through both official and unofficial channels.

Reading user reviews on tech review websites is also a good way to find out how to use the program for specific needs that may not be covered in the getting-started material; you can find out where to go for your own projects if they vary from the examples used for instruction.

Although we always advocate reading the whole process before you get started to make sure you don’t run into any surprises mid-print, if you’re confident enough in your basic skills, you can find a lot of niche advice and modifications for the base systems for whatever you need it to do.

AutoCad and Solidworks software are both comprehensive programs that will encompass all of your basic to unusual 3D printing needs.

Bottom Line Summary: Solidworks is fine for JUST 3D drafting, however I would recommend upgrading to AutoCAD here if you planning to operate a serious business with both 2D and 3D crossover needs, or may need reliable support. Autodesk IS the market leader for CAD and as such updates their products more frequently (free upgrades) and generally pioneers new features. AutoCAD also “plays better” with the other Autodesk software suites.

From beginners to professionals, Autodesk has 3D modeling software designed to meet your needs.

If you enjoyed this article you can check our guide on how to find the Best 3D Printing Cad Software.

![AutoCAD vs Solidworks [2022]: Which is The Best?](https://total3dprinting.org/wp-content/uploads/2019/01/AutoCAD-vs.-Solidworks-for-3D-Printing.png.webp)