- Ultimaker S3 vs S5 Comparison [2022]: Is It Worth The Upgrade? - April 5, 2022

- Ultimaker S3 Review: Is the Ultimaker S3 Worth It? - April 4, 2022

- Anycubic Photon Mono Review: Is It Worth Buying - April 3, 2022

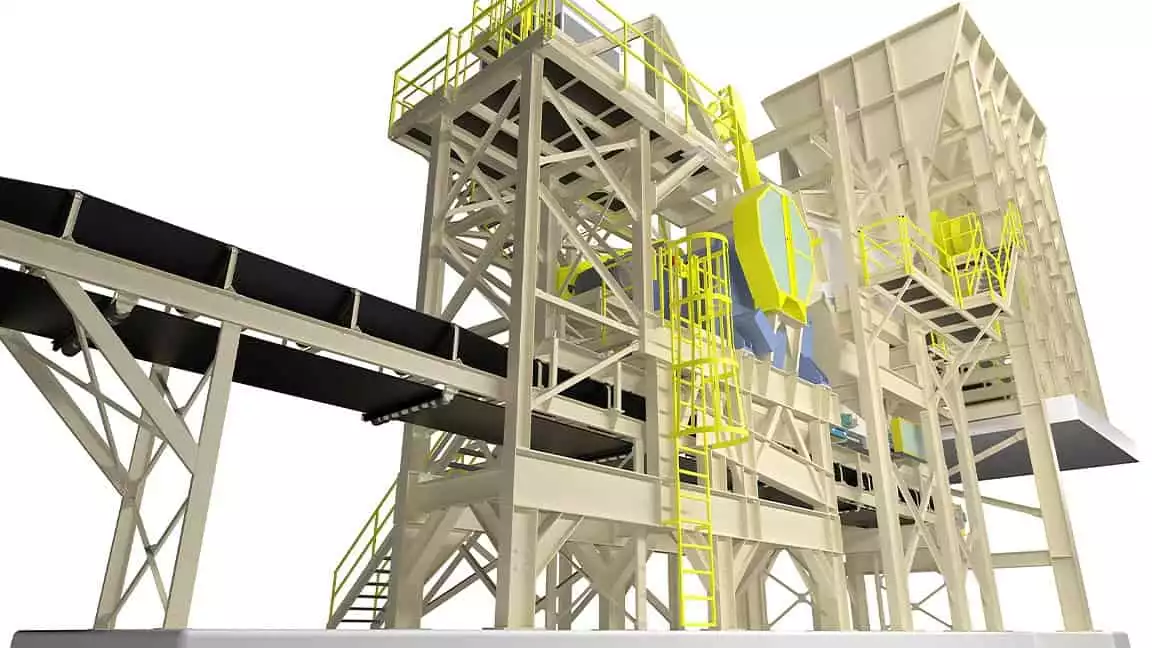

When designing a prototype or creating something that you’d like to print, you can rely on CAD software to help you with the task. Two of the most recommended programs are SolidWorks vs Inventor. These two give you a range of excellent and easy to use tools to help you create and fine-tune 3D objects for your printing needs.

But if you look into these two more closely, you’d find that some things are different and these differences may help you decide to choose one over the other.

Table of Contents

Main Differences Between Solidworks vs Inventor

The main differences between Solidworks vs Inventor are:

- SolidWorks costs more upfront, whereas Autodesk Inventor is available on a subscription basis that may be cheaper at first, but tends to add up over time.

- SolidWorks is known for being easy to learn and intuitive to use, whereas Autodesk Inventor comes with a steep learning curve.

- SolidWorks has a growing and large user community that you can tap if you have problems or questions. whereas Autodesk doesn’t have such an offer within their products.

- SolidWorks works with resellers that can give you better technical and customer support either via phone or e-mail, whereas Autodesk Inventor users are told to use e-mail for their questions.

- SolidWorks has more career opportunities available for users, whereas Autodesk has a slim selection of companies and industries that require their employees to have Autodesk Inventor experience and skills.

So what should you know about SolidWorks and Autodesk Inventor? Which one is better for you? What are the features and tools that they offer? Pull up a chair, get yourself some coffee, and read on!

What is SolidWorks?

SolidWorks is a suite of tools that allows you to make, publish, simulate, and manage everything about your project and data. The range of products offered is very easy to use and learn. SolidWorks makes designing a lot easier.

The first SolidWorks package was released in 1995, which makes it older than some millennials. Dassault Systemes originally made it to be a complete 3D modeling program that works on Windows, but it has since added features that allow it to compete with the best computer-aided engineering and computer-aided design software.

Over the years, SolidWorks also launched simulation and virtual reality features. Today, design and engineering professionals use SolidWorks for stress testing and prototyping.

SolidWorks Features You Should Know

SolidWorks comes with several tools and features that can make life easier for you. First, they have the sustainability tool that will give show you how your design will impact the environment.

SolidWorks also offer you a range of simulation tools that helps you see how your design will hold up to different temperatures, stress, or pressure. In short, you can see how that particular design will perform in real-world conditions without you having to build it first to test it.

But what makes SolidWorks a more noteworthy program is their use of virtual reality and augmented reality. No longer are you just confined to simulations, you can test your design in different situations and environments.

SolidWorks’ design review can also accommodate millions of components because of its large size. What’s more, you can work with all the components you need without draining your CPU’s resources.

How Much does SolidWorks Cost?

SolidWorks charge both for its license and upgrades. You pay $3,995 for the license and then pay another $1,295 for upgrades and support.

- is the cheapest option but it already has all the and tools that other versions offer, plus basic rendering and animation tools.

- SolidWorks Professional adds tools and features for design checking, visualization, and costing, as well as photo-realistic rendering. Professional also allows you to use a scan of a part and reverse engineer it.

- SolidWorks Premium is the most expensive version and gives you access to all the features offered by SolidWorks. You will probably need this version if you use simulation tools extensively, as well as routing features.

| Product | Permanent license | Annual subscription |

| Design | ||

| SolidWorks Electrical Professional | $9,995 | $2,750 |

| SolidWorks Premium | $7,995 | $1,995 |

| SolidWorks Electrical Schematic Professional | $5,995 | $1,695 |

| SolidWorks Electrical 3D | $5,995 | $1,695 |

| SolidWorks Professional | $5,490 | $1,495 |

| SolidWorks Standard | $3,995 | $1,295 |

| Design validation | ||

| SolidWorks Plastics Standard | $4,995 | $1,499 |

| SolidWorks Simulation Professional | $4,177 | $2,375 |

| SolidWorks Simulation Standard | $3,995 | $1,000 |

| SolidWorks Plastics Premium | $22,495 | $5,624 |

| SolidWorks Plastics Professional | $14,995 | $3,794 |

| SolidWorks Flow Simulation | $13,995 | $3,919 |

| SolidWorks Simulation Premium | $11,595 | $3,675 |

| Data management | ||

| SolidWorks PDM Professional Viewer | $2,995 | $995 |

| SolidWorks PDM Professional CAD Editor | $1,895 | $495 |

| SolidWorks PDM Professional Contributor | $1,350 | $395 |

| Technical communications | ||

| SolidWorks Composer | $5,490 | $1,495 |

| SolidWorks Inspection Professional | $3,995 | $999 |

| SolidWorks Inspection Standard | $2,295 | $599 |

| SolidWorks MBD Standard | $1,995 | $499 |

| Sustainable design | ||

| SolidWorks Sustainability | $2,995 | $995 |

As you can see, there are a lot of flavors for SolidWorks, so it’s best to talk to a reseller about what you need and allow them to match your requirements with the right version.

What Might Need Improving About SolidWorks

One of the things that you might not like about SolidWorks is the fact that it doesn’t offer students and teachers a free license for their software. Users from the academe can download the student edition, which will cost them $99, and that only lasts for a year.

See how SolidWorks compares to others:

What is the Autodesk Inventor?

Autodesk Inventor came four years after the first SolidWorks came out. The inventor directly challenged SolidWorks as it is also a tool for a mechanical design that allowed you to work with both 2D and 3D designs. It also had a good set of simulation and documentation tools.

How Much Does the Autodesk Inventor Cost?

Autodesk uses a subscription model for Inventor, requiring you to pay $1,985 per year. You can save by paying for a three-year subscription at $5,360.

Autodesk Inventor Features Worth Noting

Autodesk Inventor has some editing tools that make your work faster. First, it automates the math behind complex designs. for example, if you’re designing a kinetic blade, the program will do the advanced math behind the scenes, so you can concentrate on designing while Inventor takes care of the minute details.

Professional-grade 3D CAD software for product design and engineering. This software provides professional-grade 3D mechanical design, documentation, and product simulation tools.

You can also do some direct editing and free-form drawings, on top of the parametric design. Software like the Inventor and SolidWorks use parametric modeling, wherein your design’s geometry will be based on and changed by certain values.

The free-form modeling and direct-edits capabilities of Inventor allow you to break free of parametric modeling. Further, the Inventor has simulation features that can help you see how your 3D designs work in real-world situations. You can simulate pressure on the joints, or see what happens when a welded part gives way.

Aside from these design and simulation features, Autodesk Inventor is also noteworthy because of its speedy loading times. The program loads your design in lightning-fast times because it can ignore the resources-hogging geometric data when you open a design.

Lastly, Autodesk Inventor offers students and teachers a free subscription. The three-year free plan will be excellent for academics to save a lot of money and still be able to use and learn Inventor, as well as other Autodesk products.

What You Won’t Like About Autodesk Inventor

Autodesk Inventor is notorious for being too difficult for beginners to learn. Autodesk products are not known for ease of use and for being user friendly.

What makes matters worse is that Inventor doesn’t have a thriving online community that can help you when you hit a wall. Autodesk tries to make up for this by releasing support materials and tutorials.

Autodesk also prioritizes users who paid for more expensive licenses for their products. So even if you’re first in line, you get bumped off if there’s somebody else who paid more to use Autodesk products.

See how Inventor compares to others:

Autodesk Inventor vs SolidWorks: The Comparison

If you’re choosing between SolidWorks and Autodesk Inventor, we can just imagine how difficult it is for you. These are both very capable CAD and CAM software that focus on machine part design and 3D rendering.

These are also forerunners in the space, with established companies behind them. They have excellent tools for visualizations and simulation.

However, to make it easier for you to decide, here’s what’s the same and what’s different with each one.

What’s the Same?

Both programs share a lot of 3D modeling capabilities as both use parametric modeling but also allow you to directly edit your designs. They both offer policy-based automation, parts library, and design tools for weldments, configurations, and even for creating with metals and plastics.

Further, they can also do the same things when it comes to visualization, utilizing animations, exploded views, lighting, materials, textures, and other visualization tools.

The Differences Between Autodesk Inventor and SolidWorks

However, these two programs do have several differences that make one better than the other. What are these?

3D Modeling Features

Autodesk Inventor has 3D modeling features that are absent from SolidWorks, including t-splines, electrical harnessing, and tube routing. However, SolidWorks does have a large design review that allows you to work with a lot of components without slowing things down.

Simulation Features

gives you the to perform finite element analysis both at the and part level, you can only do part level FEAs with SolidWorks. It also has a shape generator that allows you to fine-tune your design so that it’s lighter or smaller, but still structurally efficient.

You can also do dynamic simulation and injection mold analysis with Inventor. Meanwhile, SolidWorks allows you to quickly conduct symmetry checks and geometry comparisons.

SolidWorks also has closed pipe computational fluid dynamics, which lets you see how gas and liquid can flow through your design. However, the biggest advantage that SolidWorks has over the Autodesk Inventor is its ability to use virtual and augmented reality to simulate real-world situations that can affect your design.

Costs

When it comes to costs, SolidWorks is more expensive upfront: a one-time license fee of around $4,000 for the Standard version. You can also opt to buy a subscription add-on for around $1,300. However, pricing for SolidWorks can vary depending on the version you buy and which reseller you work with.

Autodesk Inventor only charges $1,985 a year. What’s more, Autodesk offers you a free three-year subscription for their products if you are a student or a teacher.

Ease of Use

One of the things that you’d like about SolidWorks is how intuitive its user interface is, and how easy to use it is. Autodesk Inventor can sometimes frustrate users who are just learning to use it.

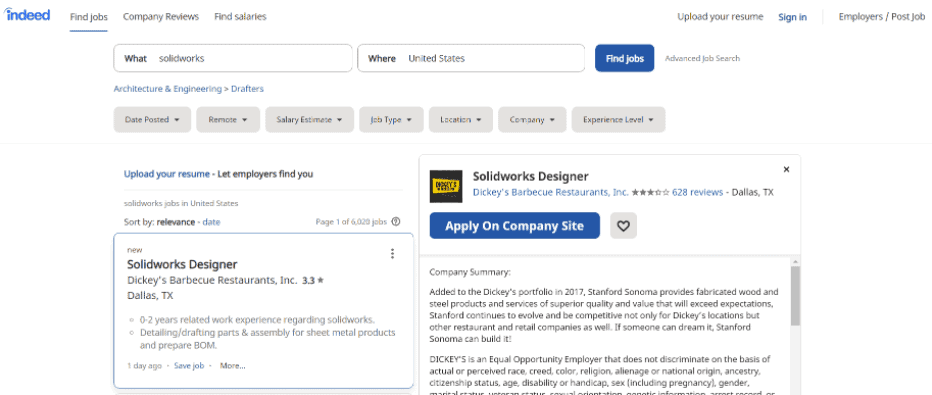

Demand

More companies are using SolidWorks than Inventor. You can see this in the jobs that require these skills. If you are currently trying to figure out which between these two is more in demand, here’s the number of job openings on Indeed and LinkedIn for SolidWorks and Inventor.

SolidWorks

Indeed.com: More than 6,000 jobs in the United States

LinkedIn: More than 25,000 jobs worldwide.

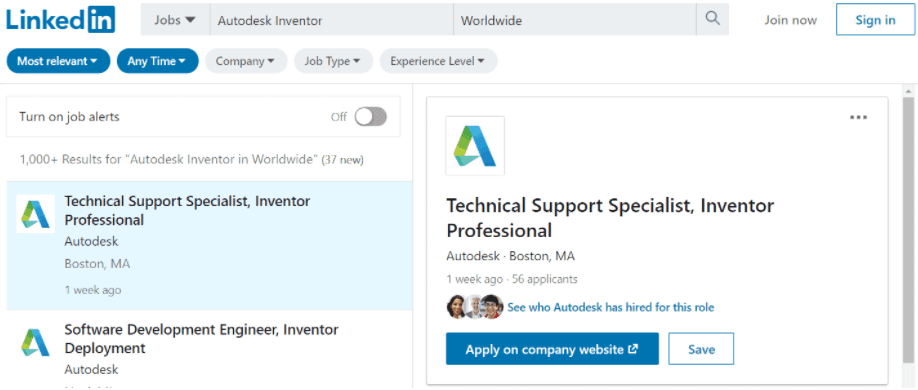

Autodesk Inventor

Indeed.com: Around 400 jobs in the United States.

LinkedIn: More than 1,000 jobs worldwide.

Side-by-Side Comparison: Autodesk Inventor vs SolidWorks

To make things easier for you, here are the costs and features of both SolidWorks and Autodesk Inventor, side by side aaa.

| SolidWorks | Autodesk Inventor | |

| License fee | $3,995 | N/A |

| Subscription (per year, per user) | $1,295 | $1,985 |

| 3D modeling features | ||

| Part modeling | Yes | Yes |

| Assembly | Yes | Yes |

| Parametric modeling | Yes | Yes |

| Mesh modeling | No | Yes |

| Hybrid modeling | No | Yes |

| Direct editing | Yes | Yes |

| B-rep surfacing | Yes | Yes |

| Rules-based automation | Yes | Yes |

| Parts library | Yes | Yes |

| Bolted connections | Yes | Yes |

| Configurations | Yes | Yes |

| Weldments | Yes | Yes |

| Sheet metal | Yes | Yes |

| Plastics | Yes | Yes |

| T-splines | No | Yes |

| Design accelerators | No | Yes |

| Electrical harnessing | No | Yes |

| Tube and pipe routing | No | Yes |

| Large design review | Yes | No |

| Simulation features | ||

| Design for manufacturing | Yes | Yes |

| Interference checking | Yes | Yes |

| Wall thickness | Yes | Yes |

| Part level finite element analysis | Yes | Yes |

| Draft analysis | Yes | Yes |

| Sustainability analysis | Yes | Yes |

| Assembly level finite element analysis | No | Yes |

| Shape generator | No | Yes |

| Dynamic simulation | No | Yes |

| Injection mold analysis | No | Yes |

| Symmetry check | Yes | No |

| Closed pipe computational fluid dynamics | Yes | No |

| Geometry comparison | Yes | No |

| AR and VR simulation | Yes | No |

| Visualization features | ||

| Animations | Yes | Yes |

| Exploded views | Yes | Yes |

| Walkthroughs and flyovers | Yes | Yes |

| Camera view controls | Yes | Yes |

| Lighting | Yes | Yes |

| Materials | Yes | Yes |

| Textures | Yes | Yes |

| Ray trace photo rendering | Yes | Yes |

Frequently Asked Questions

In this section, we answer some of the questions you might find yourself asking when deciding between SolidWorks and Autodesk Inventor.

Computer-Aided Design software allows design professionals to create more precise designs without spending too much time on it. You only create a 2D shape of the object you’re creating and the software will expand that into a 3D model that you can modify. You can add holes, snaps, and threads to the object as you see fit.

For the most part, you can also use 3D modeling software for your 3D printing needs. A 3D modeling program lets you work with 3D shapes instead of starting with a 2D printing. Some 3D modeling software even allows you to shape your 3D object like you would shape real-life clay. Check out software such as SculptGL for programs that offer this functionality.

But which one is the better bet for 3D printing enthusiasts? 3D printing

gear and other simple objects can easily be done with CAD software. But if you have more complex projects such as a character or a figurine, you will want to use a 3D modeling software.

Then again, if you are prototyping a part that you are already designing on CAD software, then you will be happy to know that you can still print these parts, just be sure that your software can save it into STL files so that you can provide the printer with the G-codes it needs to print your object.

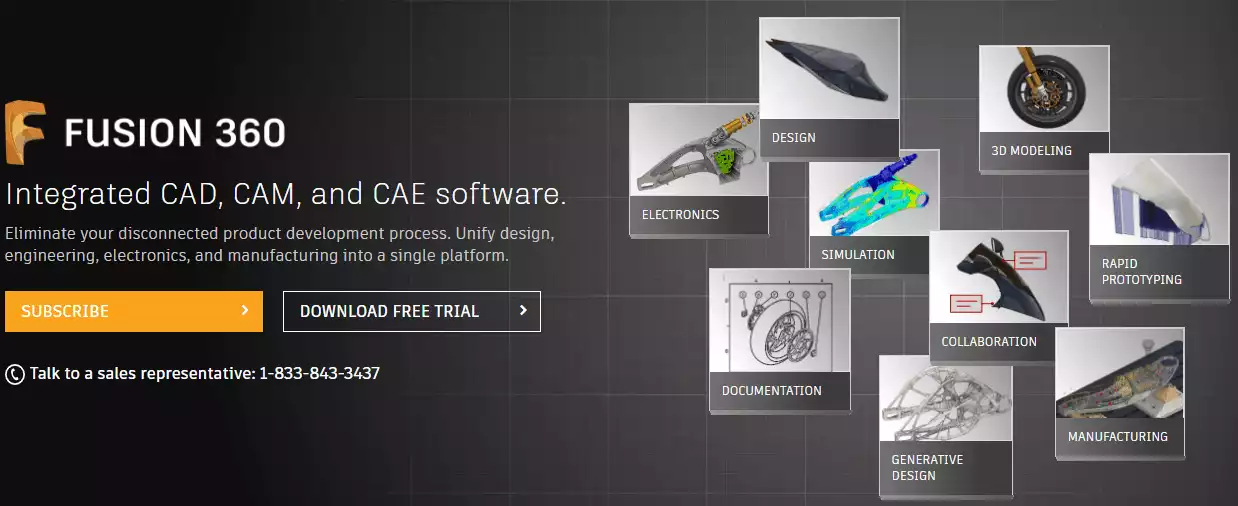

- Yes, there are worthy alternatives to both Autodesk Inventor and SolidWorks. some of these are free, while others offer something more than what Inventor and SolidWorks can give you.

- Fusion 360, a cloud-based CAD program that allows you to create complex designs and collaborate with a team of designers. What’s more, you can use the resources of the cloud to render your designs. You can store all the steps you made with the design, including the corrections and changes made along the way. Fusion 360 gives you a wide range of features and design capabilities. You pay $297 per year or it comes free for personal use.

- FreeCAD is a free program that also gives you parametric 3D modeling. If you’re still starting with CAD designs, this is a good place to start.

- AutoCAD is another Autodesk product and is one of the best and most established CAD programs out there. It comes with a steep learning curve and is better suited for 2D drafting, but it does have some 3D capabilities that you shouldn’t snub. You pay $210 per month or $1,690 per year if you choose this program.

- CATIA brings together tools and features for CAD, CAM, and CAE. As such, designers, engineers, and product designers can use this for their work. This program also allows for easy collaborations. Made for professionals, this software can be quite expensive with rates starting at $10,000.

- OpenSCAD is free CAD software that allows you to create solid 3D models. It allows you to extrude 2D drawings and create a 3D object. Programmers and coders will like using OpenSCAD but the general public will probably find it difficult to use.

Lightweight, affordable and cloud-based. Fusion 360 is more user friendly for freeform 3D modeling.

The Gold Standard for industrial CAD, AutoCAD LT can flexibly adapt to 2D or 3D projects, while using local network drives if connection speeds are limited. Most additive manufacturing speaks AutoCAD.

Autodesk Inventor vs SolidWorks: Which Should You Choose

When deciding between SolidWorks and Autodesk Inventor, you will probably lean towards SolidWorks more. It’s easier to use and has a better set of features than Inventor. What’s more, if you’re using it for 3D printing, SolidWorks has its roots in 3D modeling.

What’s more, SolidWorks has a vibrant and helpful user community. But don’t discount Autodesk Inventor just yet. This software comes from a company that may be considered as a pioneer in the CAD software space, and they do have free options for students and teachers to learn their software. They also have an excellent range of tools for 3D design.

Professional-grade 3D CAD software for product design and engineering. This software provides professional-grade 3D mechanical design, documentation, and product simulation tools.